PROCESSED CHEESE

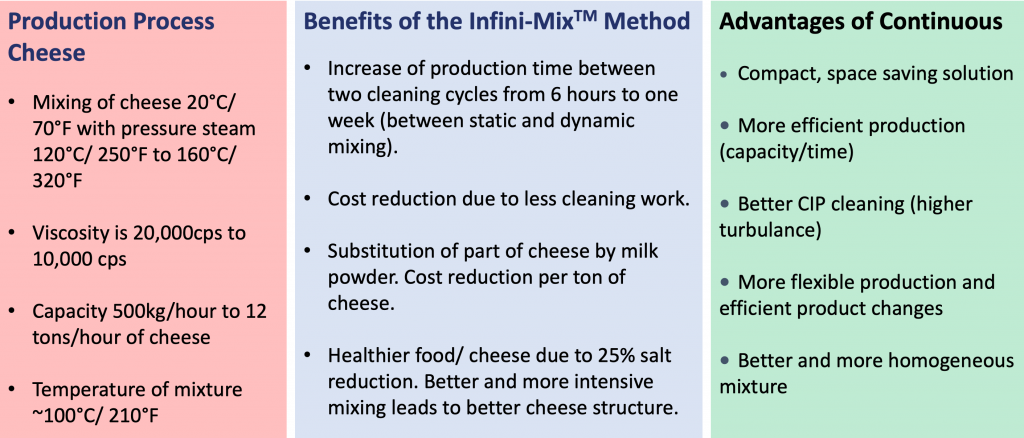

THE PROCESS

Manufacturing Processed Cheese involves blending natural cheese with a variety of other ingredients including, but not limited to, water, emulsifiers, dried whey & skim milk powders, cheese powders and lactose. The ingredients are blended and heated until a homogenous product is created.

THE PROBLEM

The emulsion created requires a moderate to high level of shear in order to create a stable emulsion.

Additionally, the powdered ingredients must be fully wetted out, hydrated and brought up to temperature. This is typically done using multi-tube heat exchangers which foul and generate scaling & build up over even short runs.

THE SOLUTION

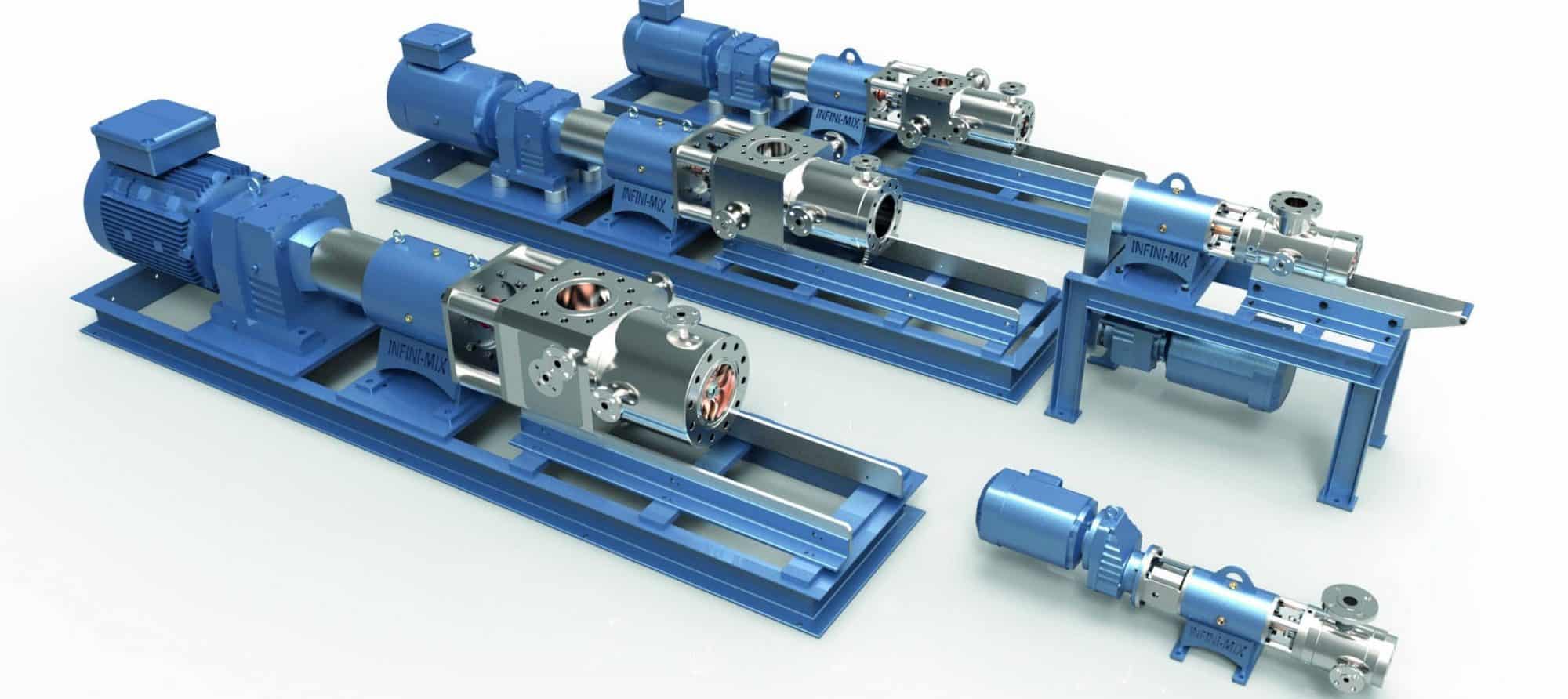

The Infini-Mix S-LG Mixer provides a high level of emulsifying shear and dispersion of steam in a continuous processed cheese process. Steam is injected directly into the mixer. The mixing elements continuous blend the ingredients and disperse the steam to cook all of the powders thoroughly and homogeneously.

There is never fouling inside the mixer and the process is fully CIP-able. This allows for longer runs and significant savings for less frequent CIP cycles.