Batch Mixers

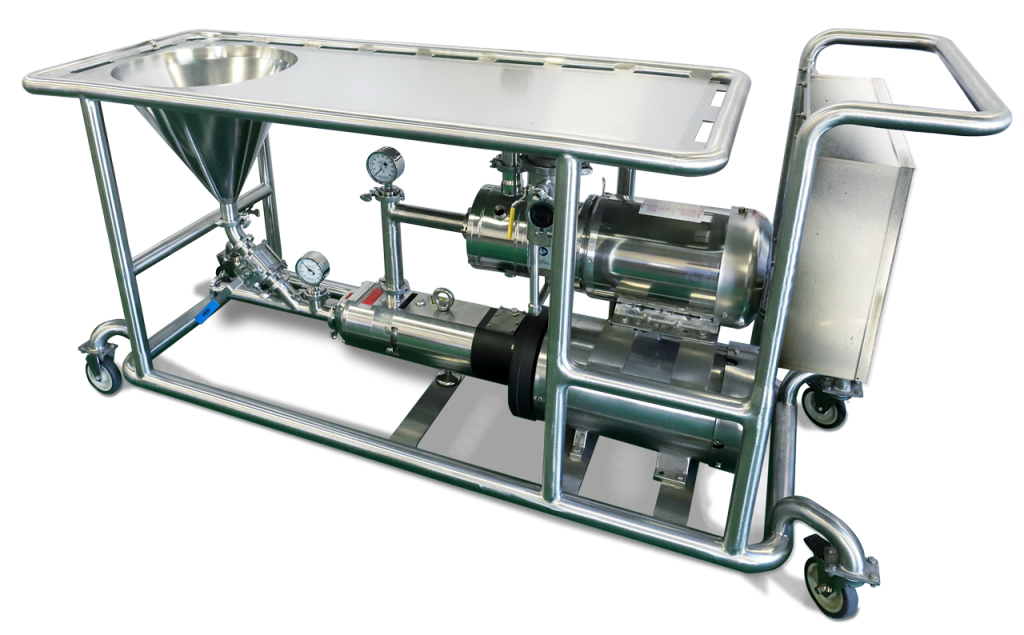

Infini-MixTM only sells Inline, Dynamic Mixers. We believe that an INLINE mixer has far more flexibility than IN-TANK, or batch mixing, solution. Unlike most batch mixing solutions, an inline mixer can be valved or easily be moved from batch tank to batch tank to perform its job. More importantly, an inline mixer on the discharge of a vessel ensures that everything exiting the vessel passes through the mixing device. This makes CIP easy and greatly reduces the need for strainers to collect “clumps” of unmixed solids.

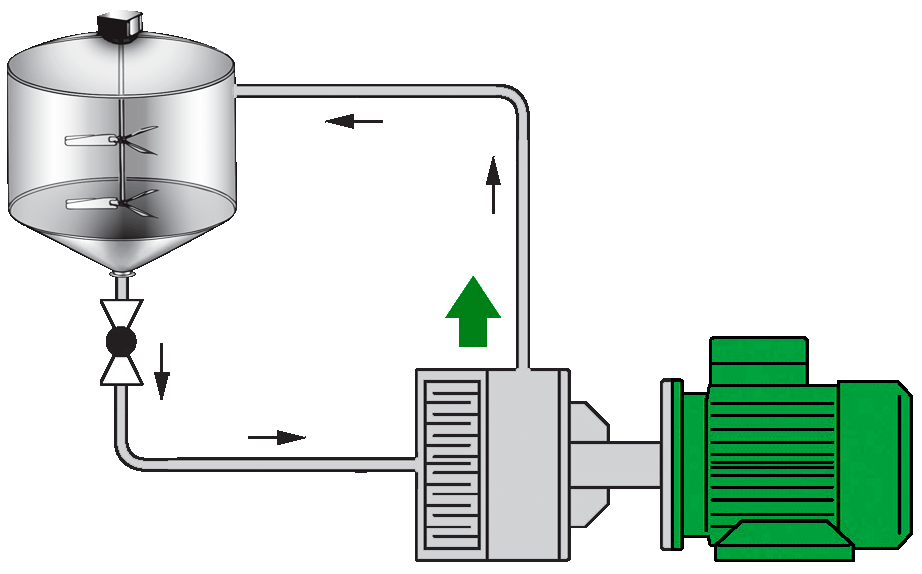

The Infini-MixTM Recirculated Batch Mixer (or RBM) pulls the solids into the liquid stream from the batch tank and recirculates the blended product back to the vessel. This solids incorporation system is far more flexible than traditional powder induction systems because of our ability to integrate ANY of our dynamic, inline mixers. The Infini-MixTM RBM system also has the ability to suck powders into a thick stream of liquid while our competitors are limited to ~2500cps.

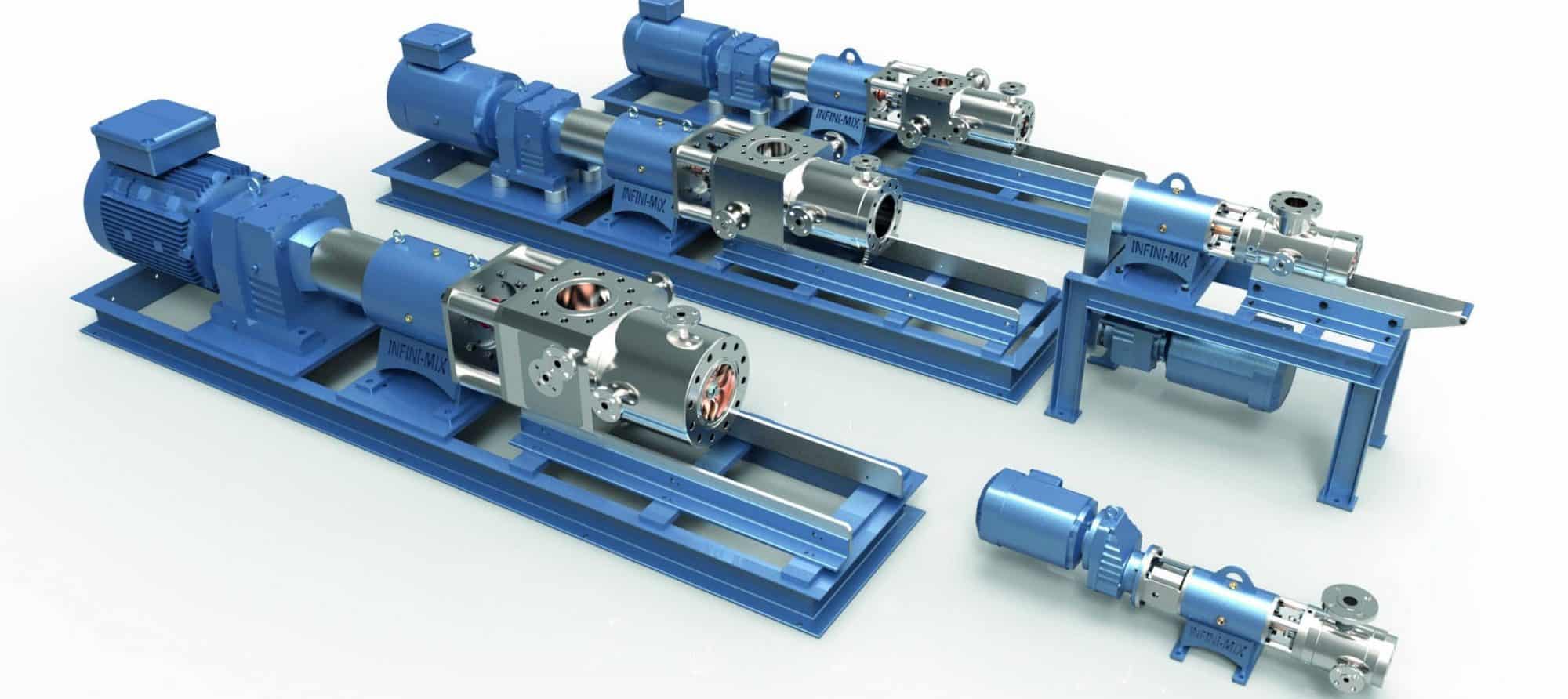

Most companies that offer inline mixers only offer medium high shear options. INFINI-MIXTM offers the full range of mixing intensities from virtually “NO” shear to “HIGH” shear. This gives us tremendous flexibility in offering inline solutions for any recirculated batch process.