Too Small for Continuous?

"We have too many recipes and small runs for it to make sense to go continuous."

This is a common misconception. Small runs with many minor ingredient adds and/or quantity changes make you the perfect candidate for going continuous. As a general rule, as a manufacturer approaches 1 ton per hour of product, changing from a batch to a continuous process starts to pay for itself. This is only ~4 GPM!

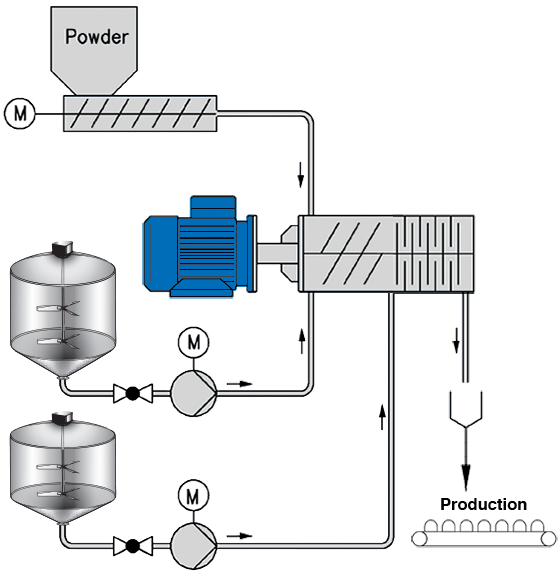

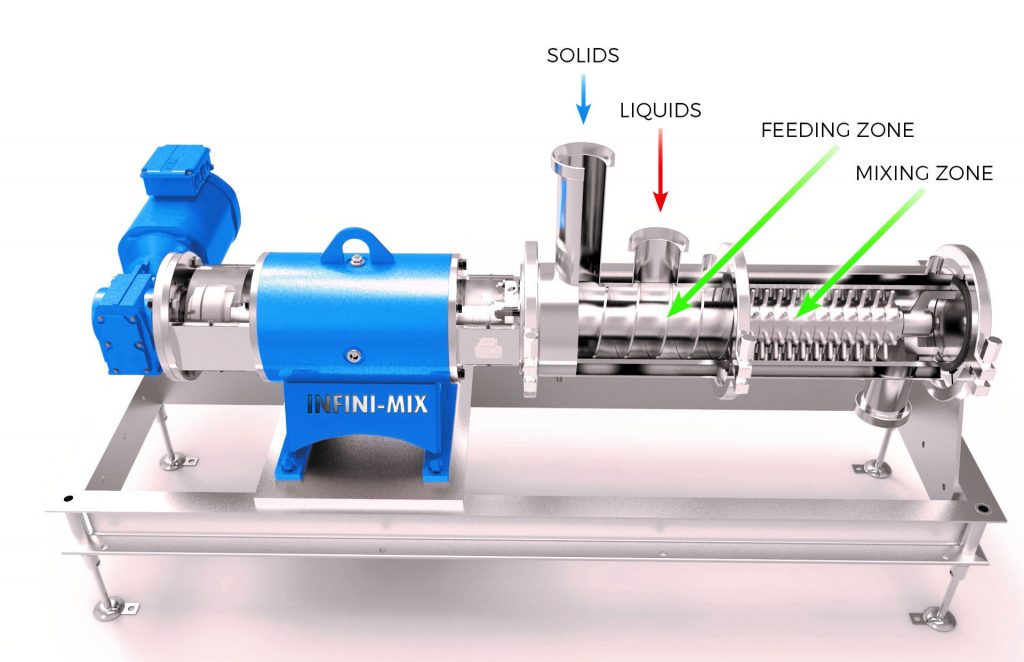

One of the easiest and most cost effective ways to start to move toward a fully continuous process is to start with “Late Stage Differentiation” or what we like to call “End of Pipe Mixing”. This is where the final ingredient, or set of ingredients, is added to the base product at the end of the process. This would be like adding the fruit flavoring to yogurt or adding the nuts or “crispies” to chocolate or blending relish or spice blends into a mayonnaise just prior to the depositor.

“We have too many ingredients."

“Our product requires a lot of residence time to fully hydrate."

“We already are continuous.”