The “Joby-Nator” Static Mixer & Pre-Wetter

PATENT PENDING 63/271,685

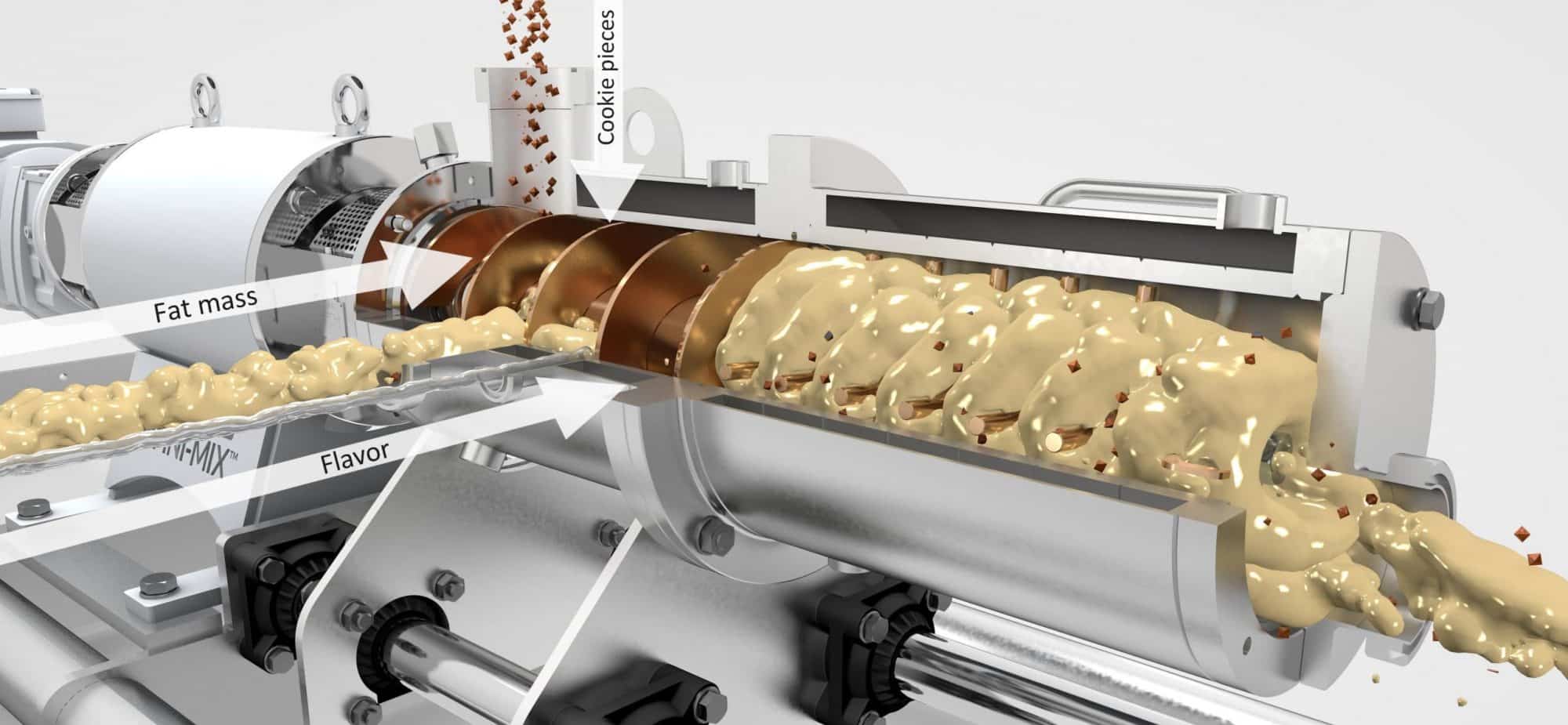

The JOBY-NATOR was born out of a need for a single pass, high rotational speed, SOLID-LIQUID mixing system. The INFINI-MIXER is ideal for low rotation speeds and applications which require more delicate handling. But how do you hydrate gums and starches or dissolve sugars and salts in a single pass when higher shear and/or additional residence time is needed?

The most common marketplace solutions for these applications are commonly called “powder induction systems.” They utilize a liquid ring pump (or some other type of pump with high vacuum capability) to draw the powders into a liquid stream and then push the pre-wetted powder through some type of high shear mixer. These systems can unnecessarily aerate the product, there is little ability to control the powder to liquid ratio and the only way to control the level of shear is to limit the number of passes through the shear device. These systems are not capable of being a single pass solution without integrating large controls packages which are very costly.

THE IDEA

All pumps, centrifugal and positive displacement, provide some level of shear. Some more than others. So why not take advantage of this potential mixing energy?

The “Joby-Nator” is a pre-wetter and static mixer which accepts multiple, direct ingredient streams for single pass blending. The ingredient streams can be solids and liquids, but a liquid component is always required.

The Joby-Nator is designed to be installed prior to any type of pump, centrifugal or positive displacement, in order to pre-wet and pre-mix the ingredients so that the pump can provide the extra mixing energy needed for a finished product or, at the very least, make the mixture “pump-able” so it can pumped through some other type of dynamic mixer. The pump selected for each application is based on several factors including, but not limited to, the product viscosity, the shear rates required for the finished product, the ability to handle entrained air and speed capability.

How Is The Joby-Nator Different from Traditional Static Mixers?

Static mixers have no moving parts. There are 2 types of traditional static mixers: those that use vacuum and those that do not use vacuum.

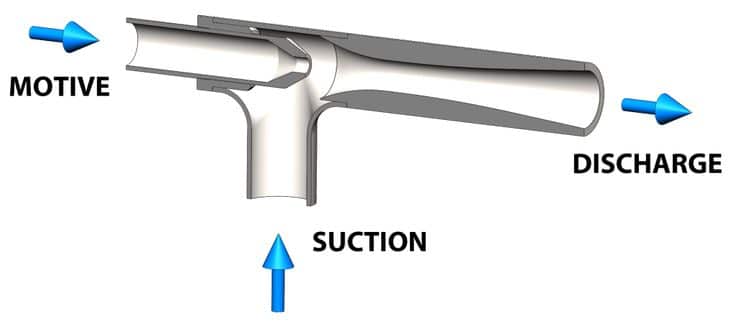

VACUUM STATIC MIXERS

Static Mixers that rely on vacuum to draw powders and/or liquids into a liquid stream are also referred to as “eductors”. A pressure and velocity is maintained across an orifice which creates a Venturi effect and the resulting vacuum sucks the additive into the liquid stream. The eductor feed rate varies with flow velocity, pressure and product viscosity. A different orifice is required for each powder:liquid ratio desired for a given system.

For this reason, eductors are good solutions for recirculated batch mixing and where high shear mixing is not required. However, this lack the flexibility makes it difficult for single pass blending.

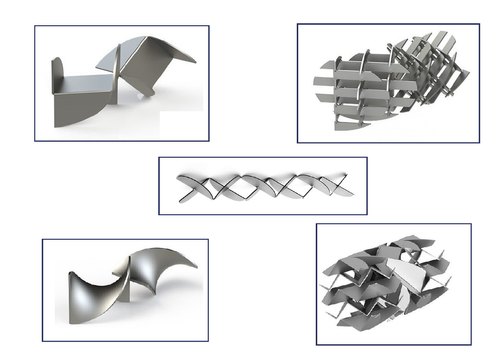

A non-vacuum static mixer is engineered to be fitted inside a pipe as an obstacle to create turbulence, and thus, a specific mixing result. These types of static mixers are used for LIQUID-LIQUID or LIQUID-GAS mixing. They are typically installed downstream of a pump.

Though some are standard “cookie cutter” inserts, most “STATIC” mixers are custom fabricated for an application. The insert is cut, bent and twisted in specific, engineered patterns in order to create the desired mixing result. The geometry can be simple or complex depending upon the complexity of the application. Most importantly, they are sized for a specific mixing result for a specific application at a given pipe velocity.

PIPE-FITTED/NON-VACUUM STATIC MIXERS

Because of the nature of an engineered static mixer, pipe-fitted static mixers are better for creating residence time in an application where time is needed for a specific result, like hydration of gums or dissolution of powders. They can have high pressure drops so they are never used on the suction side of a pump, always on the discharge side. They can also be difficult to clean, especially with products that have high solids content.

What Are Traditional Static Mixers Are Missing?

INFINI-MIX is focused on single pass mixing solutions.

Prior to the Joby-Nator, there were no non-vacuum static mixers on the market which could accept a direct ingredient stream of solids because the solids would quickly plug the mixing element.

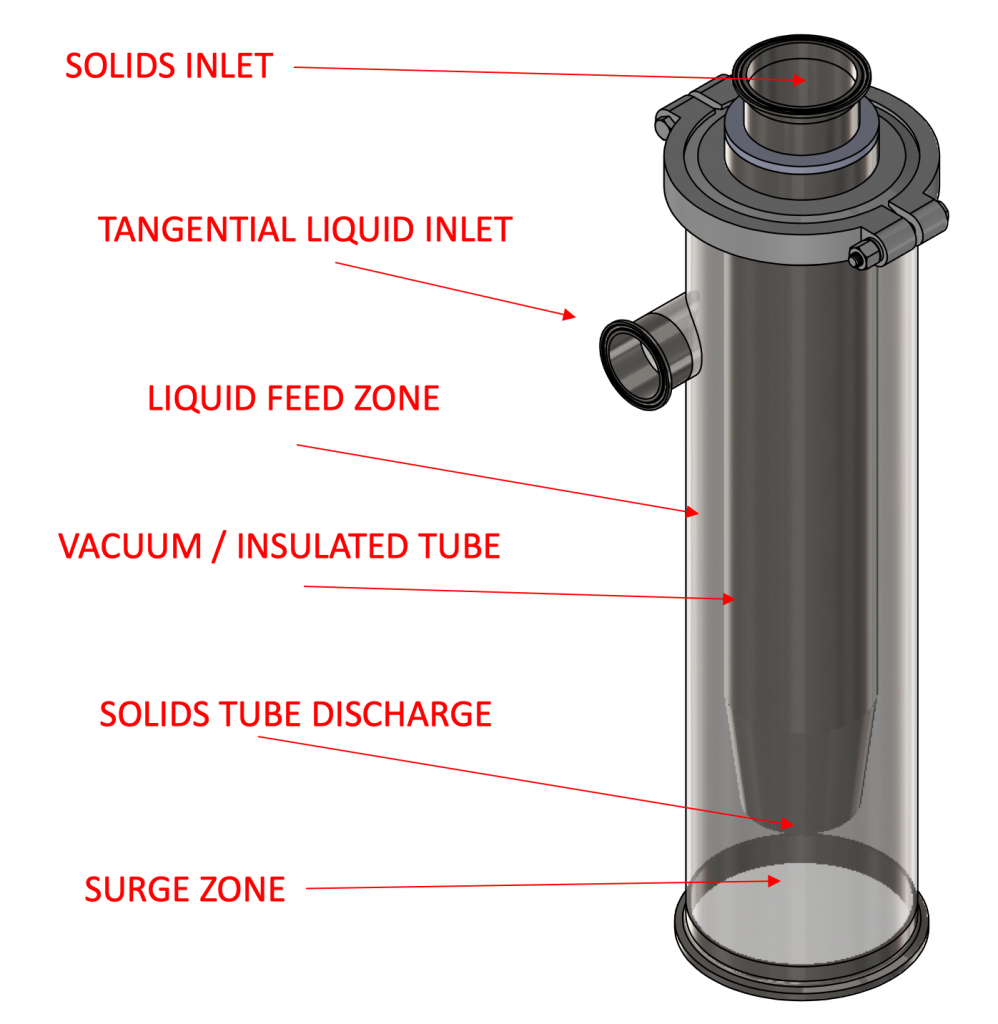

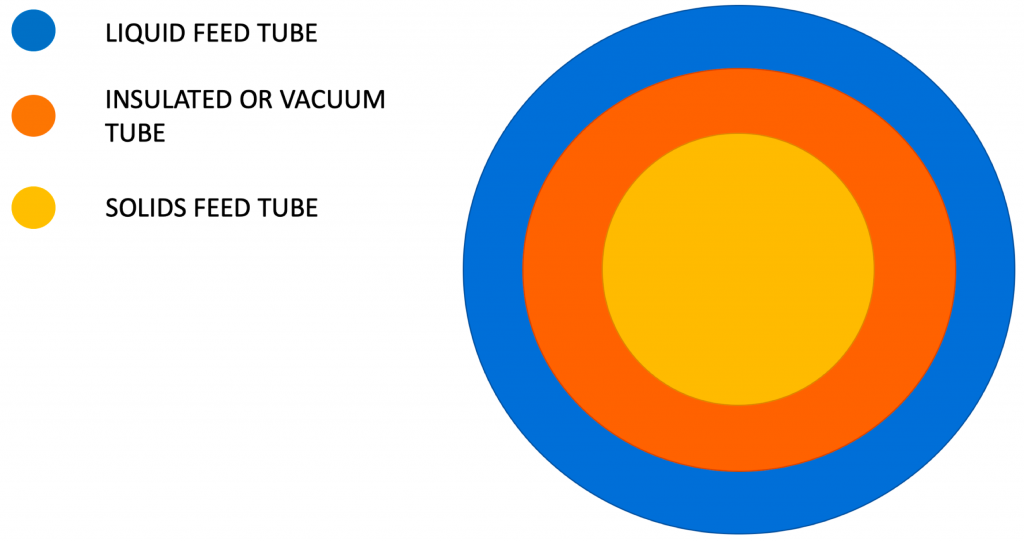

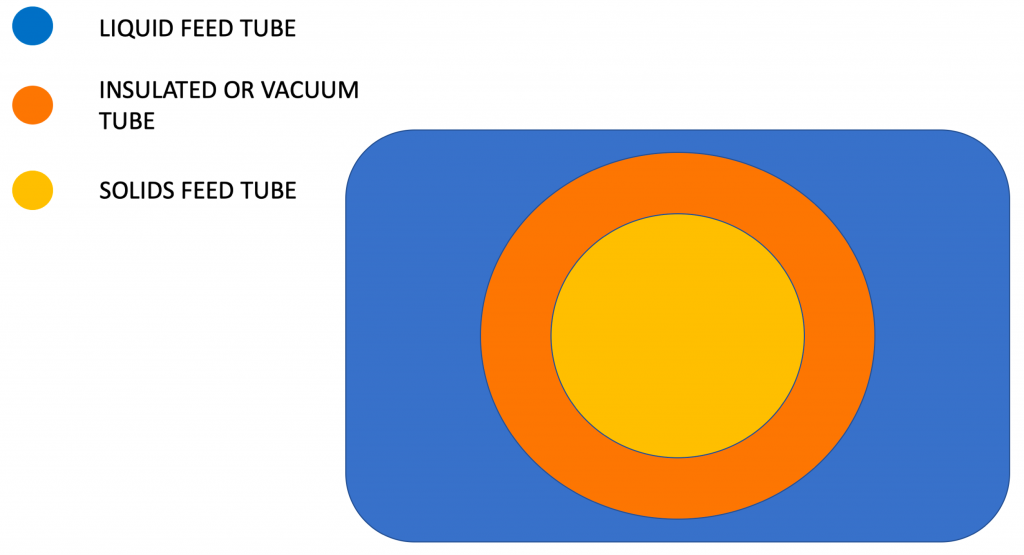

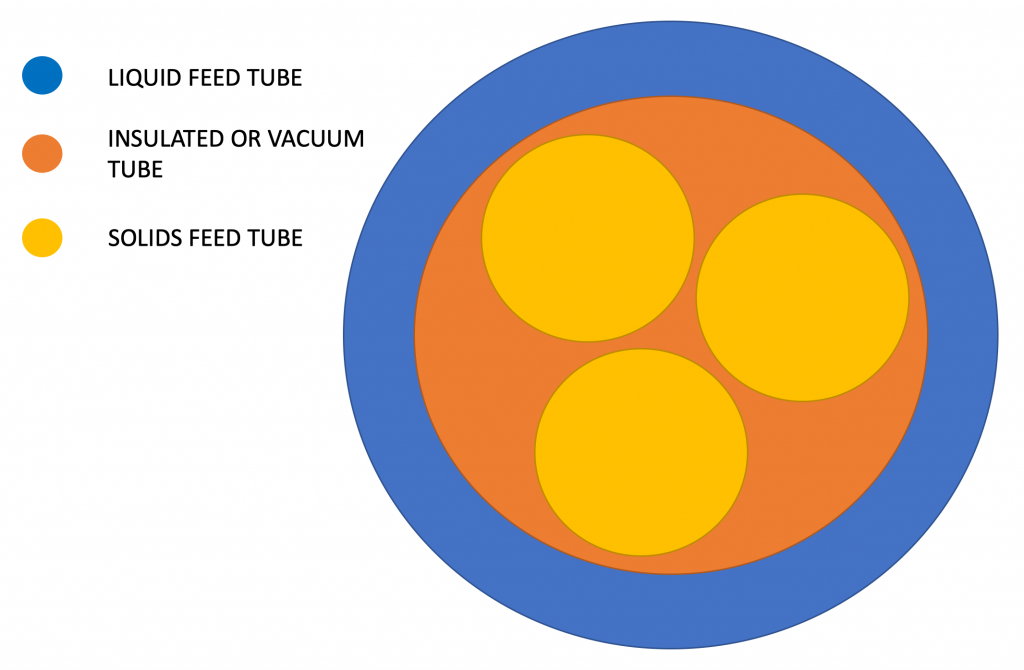

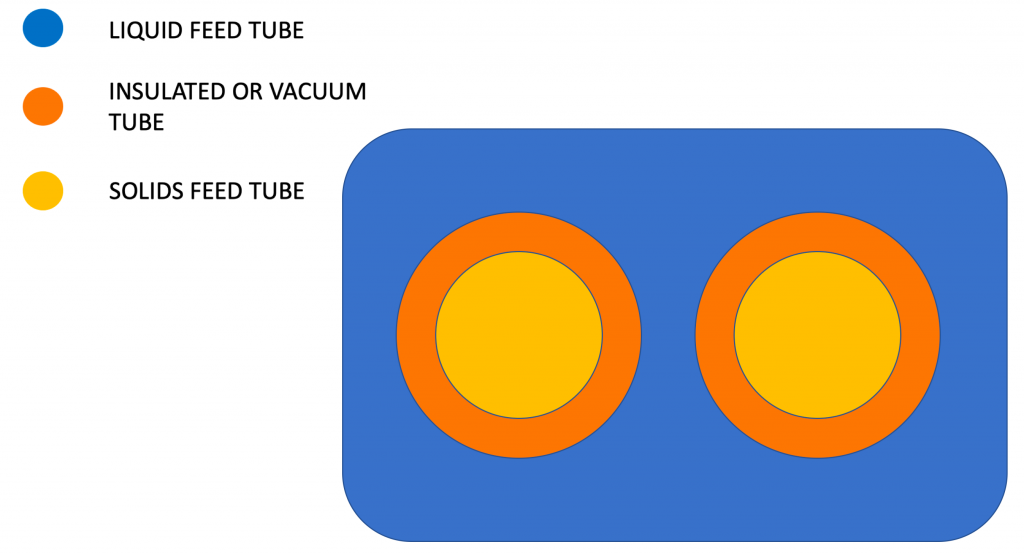

The Joby-Nator is a single pass pass solution for mixing solids and liquids. Each unit consists of various tubular sections for each ingredient stream. Each of these tubes has a characterized discharge nozzle designed to disperse on discharge into the transition area (surge zone) where all of the streams are pre-wetted prior to entering the pump.

The solids and liquid ingredient streams come together in the surge zone. The outer portion of the characterized nozzles on the solids tubes create a “cocoon of liquid” as the liquid passes over the end while the solids fall into the middle of the cocoon. This pre-wets the solids making the mixture pump-able.

This is not feeding solids into a vortex created by vacuum. This type of solution can draw air into the product.

Solids ingredient streams are metered directly into the Joby-Nator with a gravimetric or volumetric feeder and rely on gravity. Each solids stream is dispensed into a dedicated tube which is straight to ensure there is no chance of bridging or build up. Each solids feed tube has an outer tube where a vacuum is pulled to eliminate any heat transfer from the liquid feed tube(s). This helps keep the solids tubes from “sweating which can ultimately cause powder build up.

Liquid ingredient streams are metered with various types of flowmeters directly into the Liquid Feed Zone.

Multiple Variations

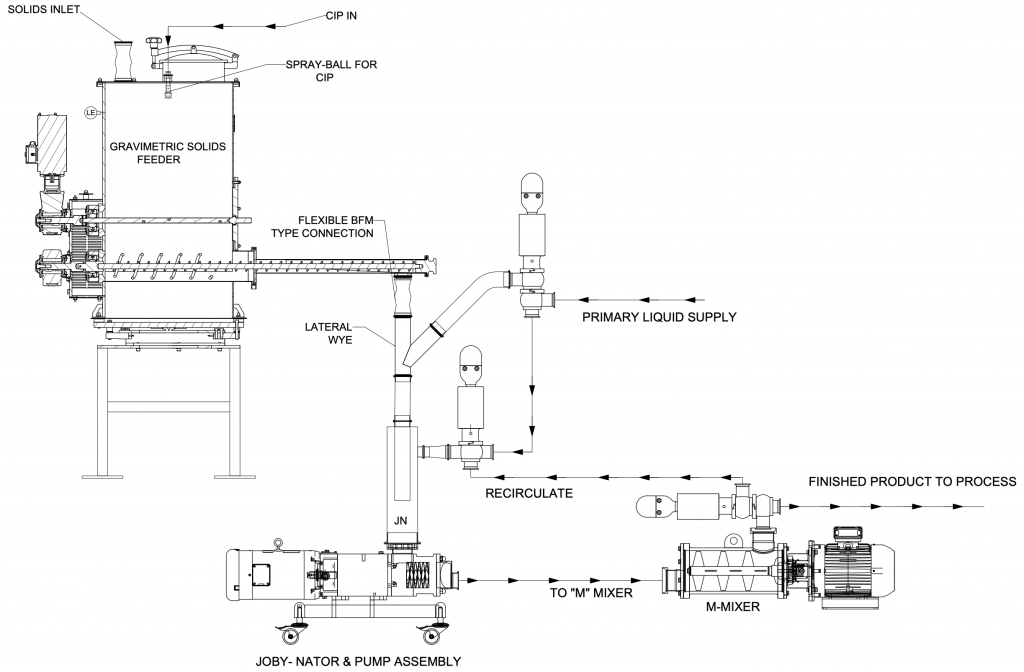

A Typical Single Pass Joby-Nator Solution

Watch it Work!

- For a standard Triple-Tube Joby-Nator:

- A gravimetric solids feeder meters the powder into the innermost tube on the Joby-Nator.

- Simultaneously, the primary liquid is metered into the outermost ring on the Joby-Nator.

- A vacuum is pulled on the ring in-between the innermost and outermost rings on the Joby-Nator so as to eliminate “sweating” on the solids tube.

- The powder and liquid come together in the “surge zone” of the Joby-Nator where they are initially pre-wetted prior to entering the pump.

- The pump transfers the pre-mix through a Dynamic Mixer for the perfect mixing result.

- Should additional residence time be required for hydration of the powder, we utilize a jacketed, static mixer sized for the appropriate hold time for hydration.

Additional Options & Benefits

- A level transmitter can be installed in the “surge zone” of the Joby-Nator to ensure the pump does not run dry or draw air into the product or allow the liquid level to rise in the surge zone and ultimately wet out the solids port(s).

- If ever the liquid level in the surge area rises and wets out the solids inlet, the solids tube must be rinsed and dried before production can re-start. In these situations, the gravimetric feeder discharge valve closes. The CIP (or rinse) is pumped to both the liquid AND the solids ports. The system can go into recirculation mode if preferred.

- Once the solids tube is deemed clean, the flow to the solids port is shut off while the outer liquid flow continues. A vent valve at the top of the Joby-Nator is opened and the level in the surge zone is kept as low as possible so that the pump will draw air flow through the center port. This will dry the center port so that powder flow can restart without issue.

- These systems can be operated manually or PLC-controlled. Simply provide a controlled flow of the primary liquid to the Joby-Nator and the system will take care of the rest.

The Joby-Nator is a simple solution for anyone who wants to mix solids and liquids in a single pass. They are relatively inexpensive and simple to install before any pumping technology.

This solution rounds out the entire INFINI-MIX offering. Our customers can perform any type of mixing (LIQUID-LIQUID, SOLID-LIQUID or LIQUID-GAS) at any level of mixing intensity.

North American Process, Inc. offers both pilot plant testing at our facility in Mora, MN and a trial pool if you would prefer to do the testing in-house.