Delicate Blending

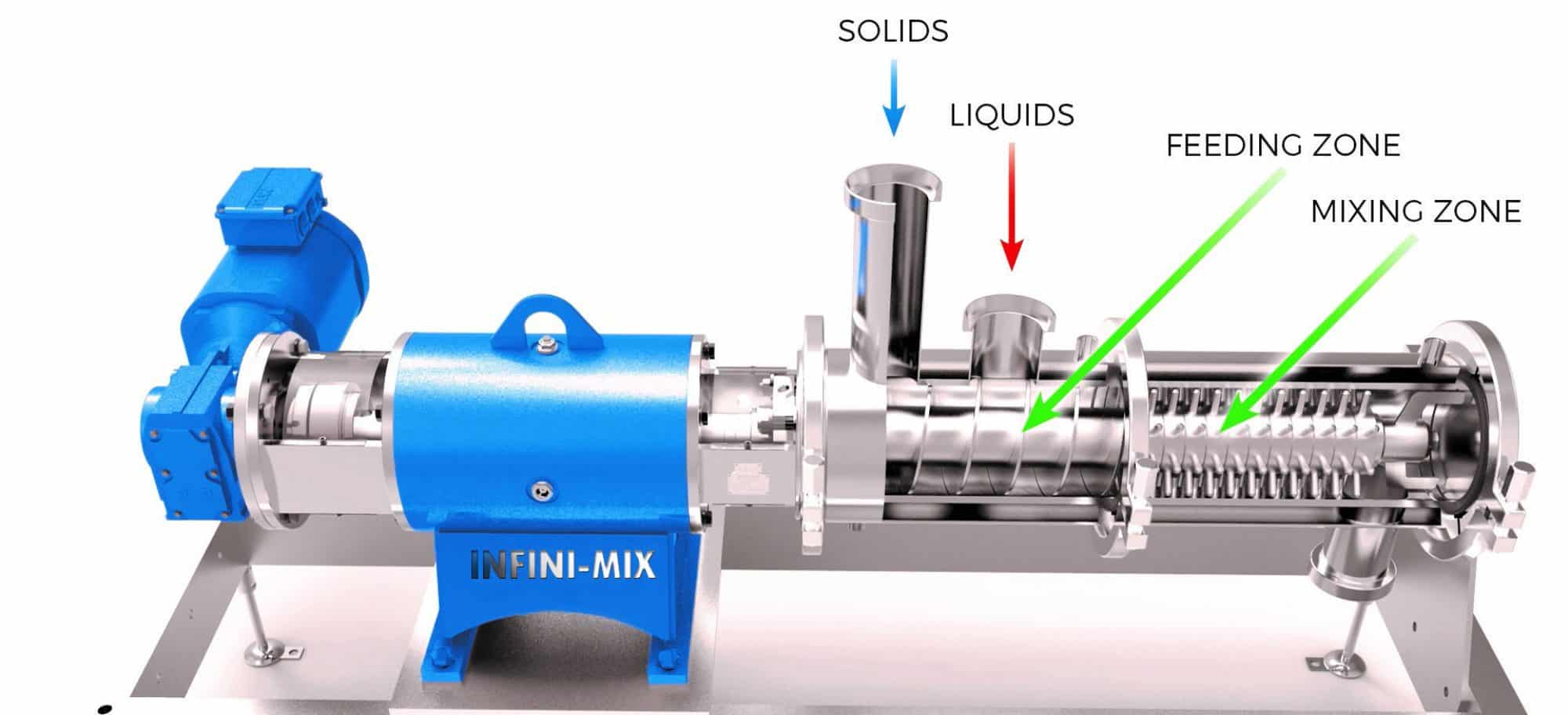

The Infini-Mix "M" Series Mixer

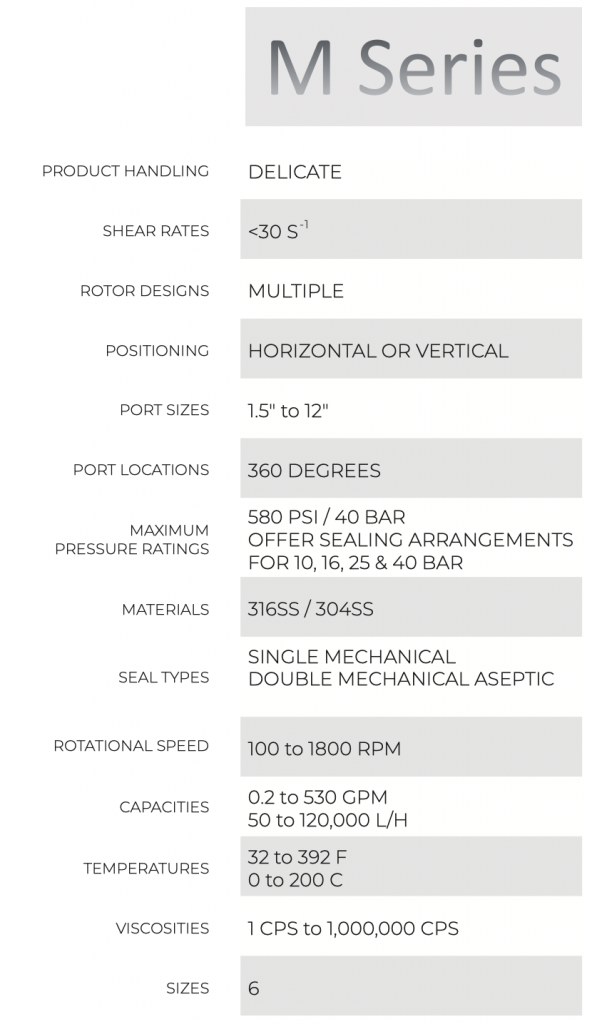

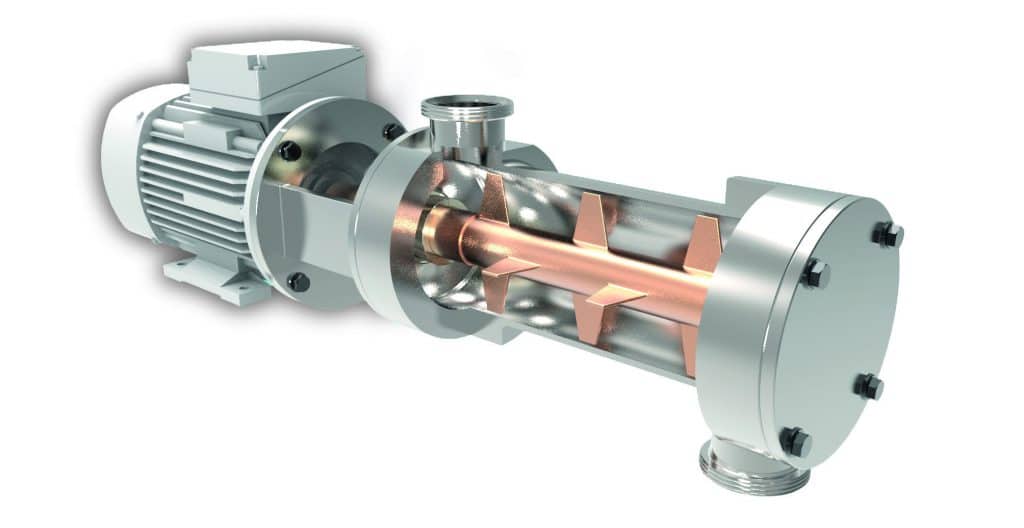

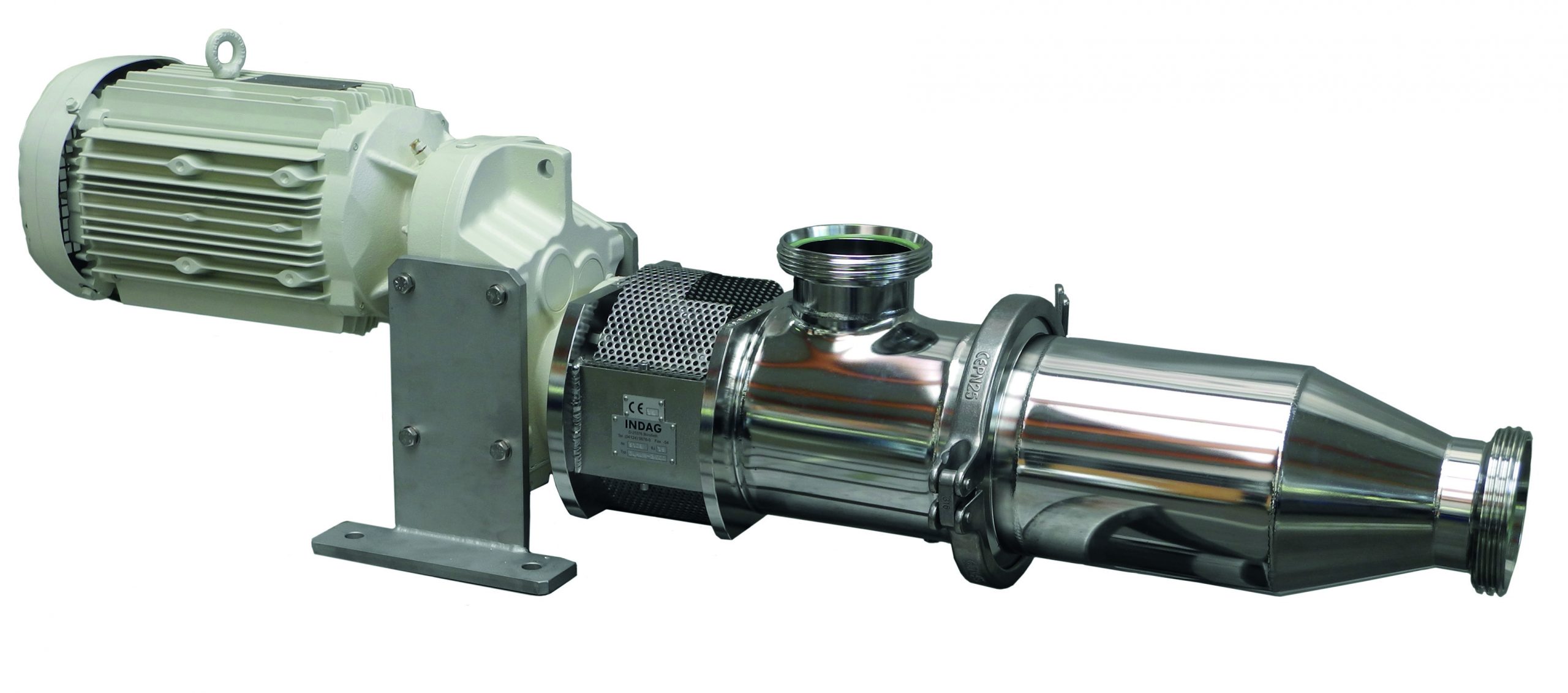

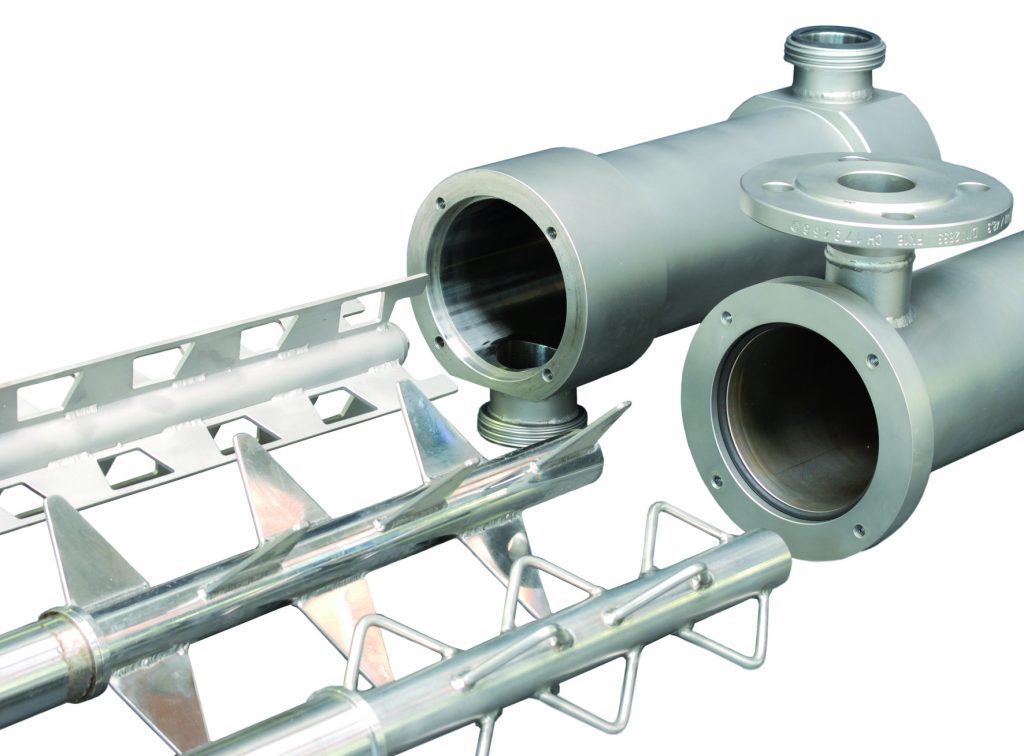

The Infini-Mix™ “M” Series mixers (DLM and ECO versions) are for delicate blending of multiple liquid ingredient streams. Gently mixing fruit prep into white mass for traditional yogurt or blending minute amounts of flavoring or coloring into ice cream are both common applications for this unit. Any liquid with a delicate structure or large solids or sensitivity toward slight temperature changes is ideal applications. The “M” series mixer will maintain the highest levels of product integrity.

Also, the M series mixer is a perfect solution for easy liquid-liquid blending applications where high shear is not required. Since most inline mixer companies only offer “high shear,” the M series mixer is a lower-cost alternative for easy applications like blending flavor concentrates into beverages or pulp into juice.

The biggest competitor of the M series mixer is the “static mixer.” The static mixer is an engineered obstacle that fits inside a pipe. It is designed for specific mixing results at a given flow rate and velocity.

In contrast, any single M series mixer has no pressure drop, is fully CIP-able, and can handle a much wider range of products and an extremely wide range of flow rates. This flexibility makes this delicate mixer the perfect solution for any liquid-liquid application where low levels of mixing intensity are required.

So Many Options!

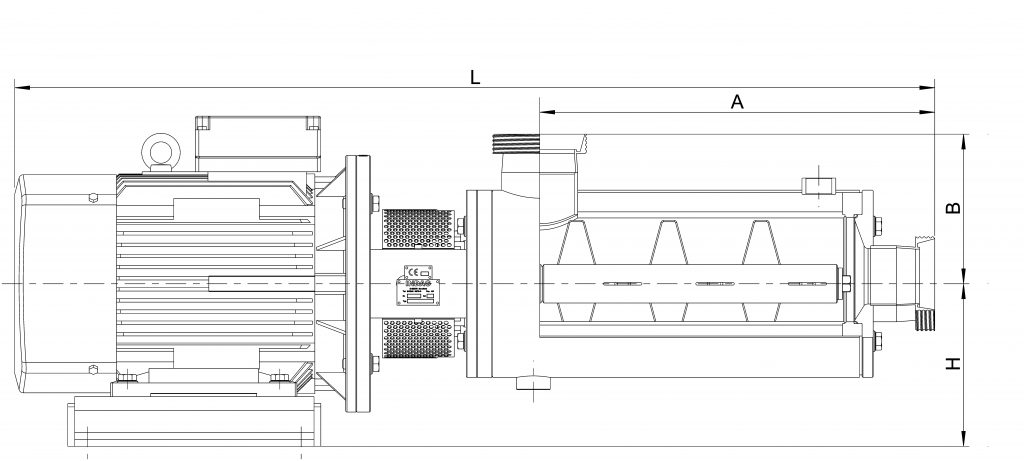

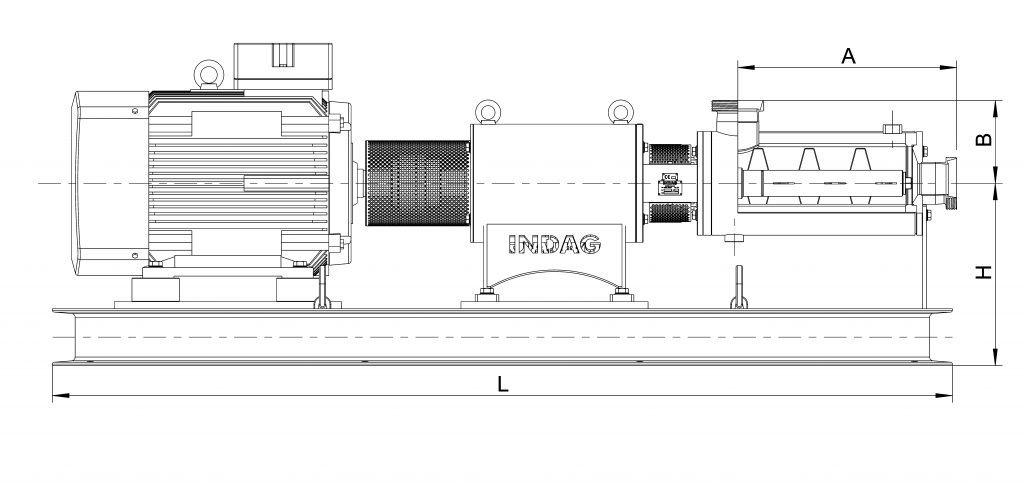

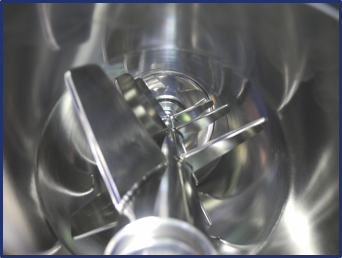

Additionally, this mixer uses any number of uniquely designed rotors to simulate manual stirring. All rotor designs have rounded edges and are designed for low rotational speeds to maintain the highest level of product integrity. The “M” Series mixer can be installed horizontally or vertically. The low volume design means less product loss when changing over recipes.

The delicate mixing of the “M” Series mixer is complemented by the delicate handling of the twin screw pump. The pumps deliver the white mass and fruit preparation to the mixer without viscosity or solids degradation. The mixers and the pumps can be configured to pass solids over 2″ diameter.

EXAMPLE

In a yogurt blending application where delicate blending is required, white mass and fruit prep are metered directly to the “M” series mixer. The mixer is installed directly above the depositor. When production calls for a flavor change, simply clean the fruit line feeding the mixer, the mixer itself, and the filler bowl and you are on to the next flavor. There is no need to clean the process lines or any batch tanks. This is a tremendous cost saving when downtime and cleaning costs are drastically reduced.

Some yogurt producers hook the aseptic fruit totes directly to their blend takes. In these situations, the product loss is even less. Simply swap the feed hose from the fruit tote. The only product loss is what is in the mixer.