HIGH SHEAR MIXING

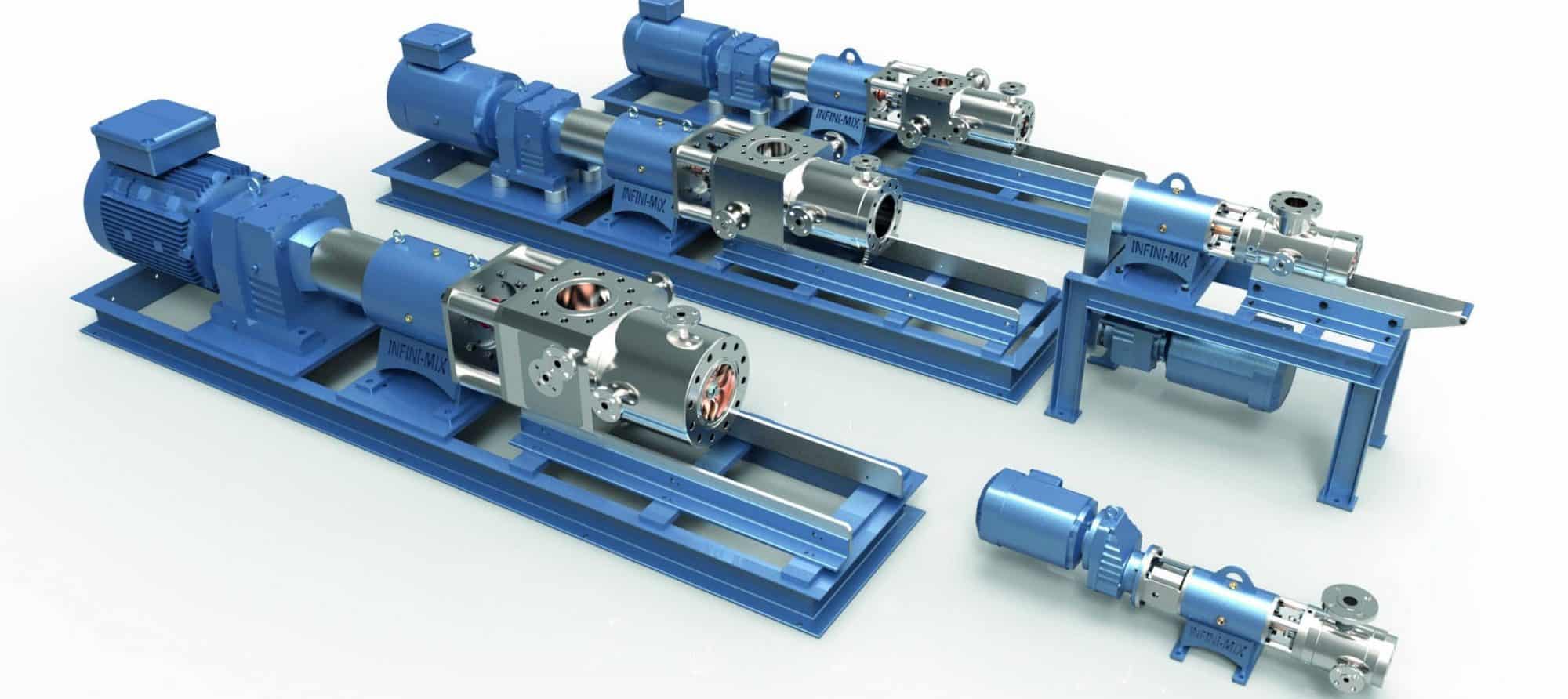

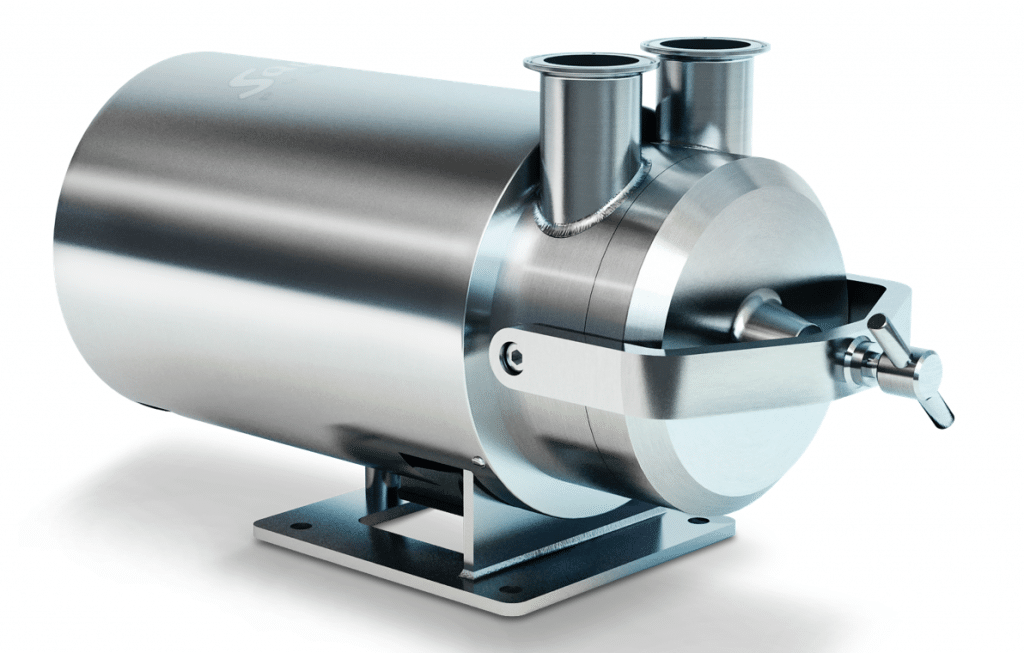

The INFINI-MIX "H" Series High Shear Mixer / Homogenizer

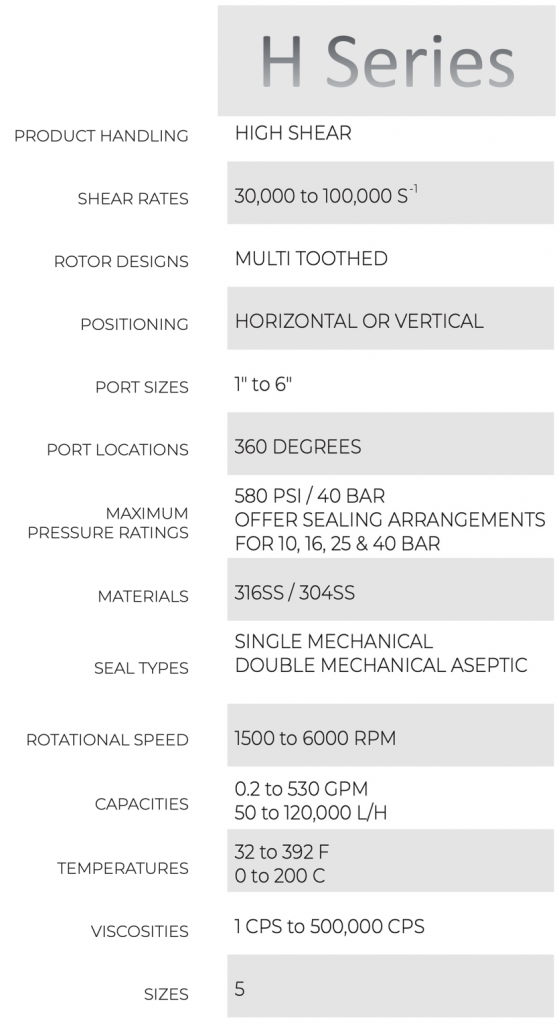

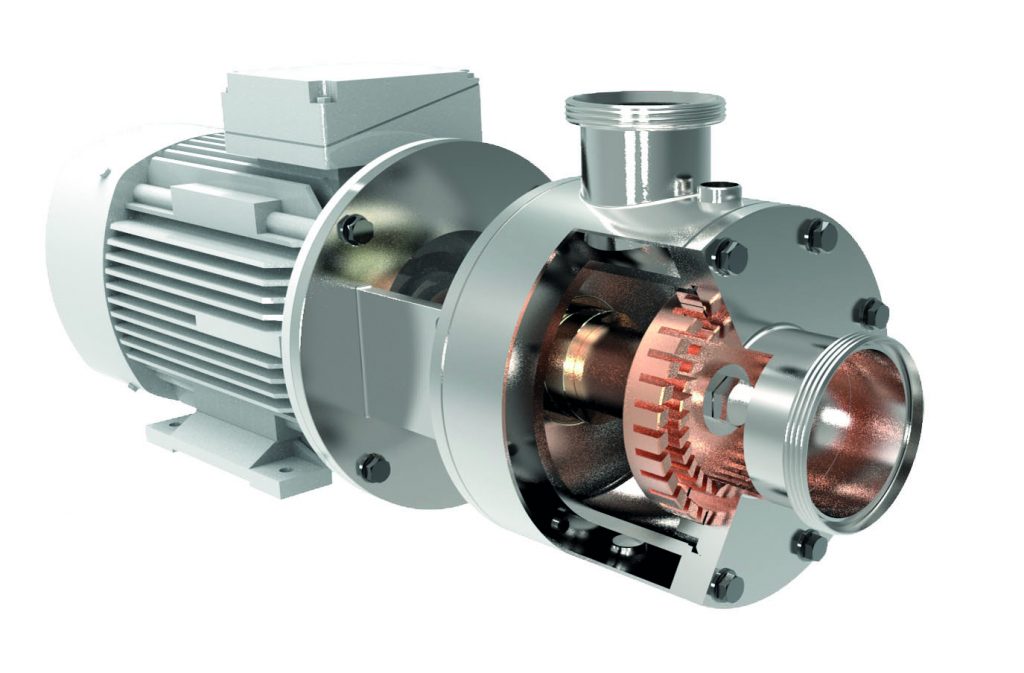

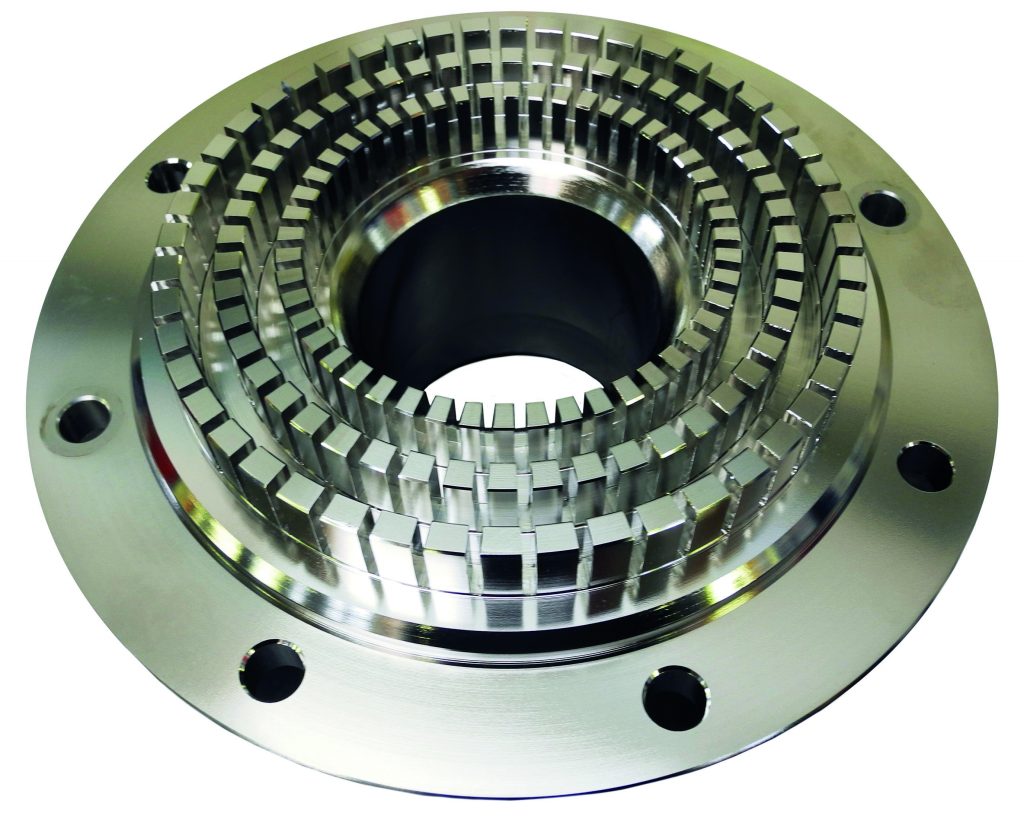

The Infini-Mix™ H-Series Dynamic Mixer & Homogenizer is for High Shear Mixing, emulsifying and true suspension. Capable of reducing globules to ~2 micron, this mixer is ideal for shearing hydroscopic gums and thickeners in a single pass. The powders are thoroughly dispersed in the workhead through a series of tight tolerance mixing elements to create hydraulic shear.

The H-Series mixer is capable of receiving multiple liquid ingredient streams simultaneously. Unlike our competitors, our sanitary mixers can handle pressures in excess of 500 PSI and temperatures up to 375°F! All mixers come standard with a jacketed housing for heating and cooling functions.

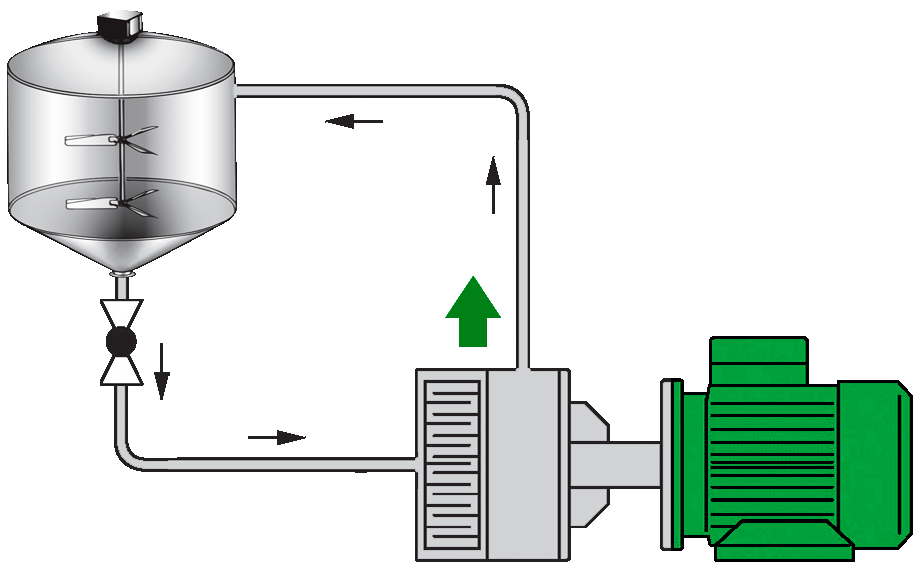

Using An Inline Mixer in a Batch Process

Nearly all inline high shear mixer manufacturers offer some type of powder induction system. These are used in a recirculated batch process. Once all of the powders are pulled into the liquid, the slurry must make multiple passes through the high shear mixer for the batch to be homogeneous.

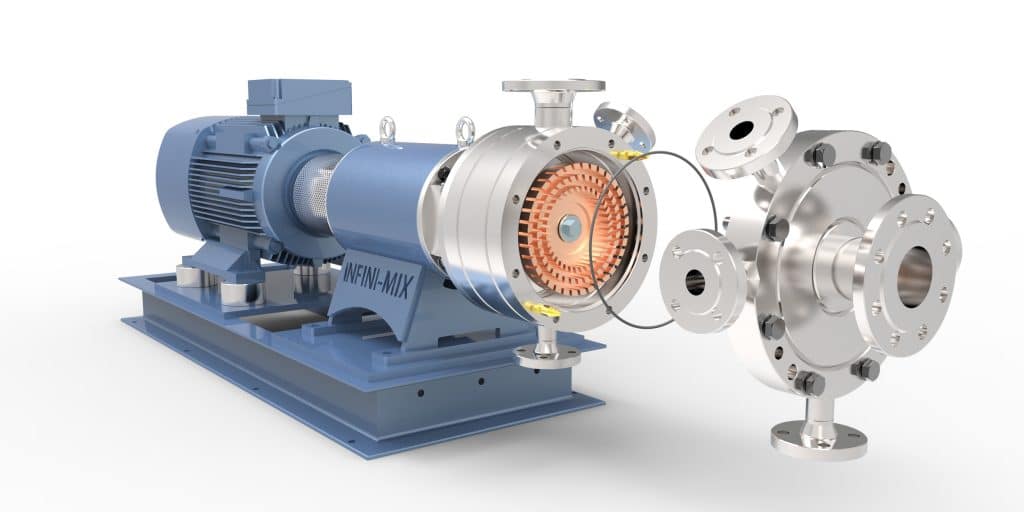

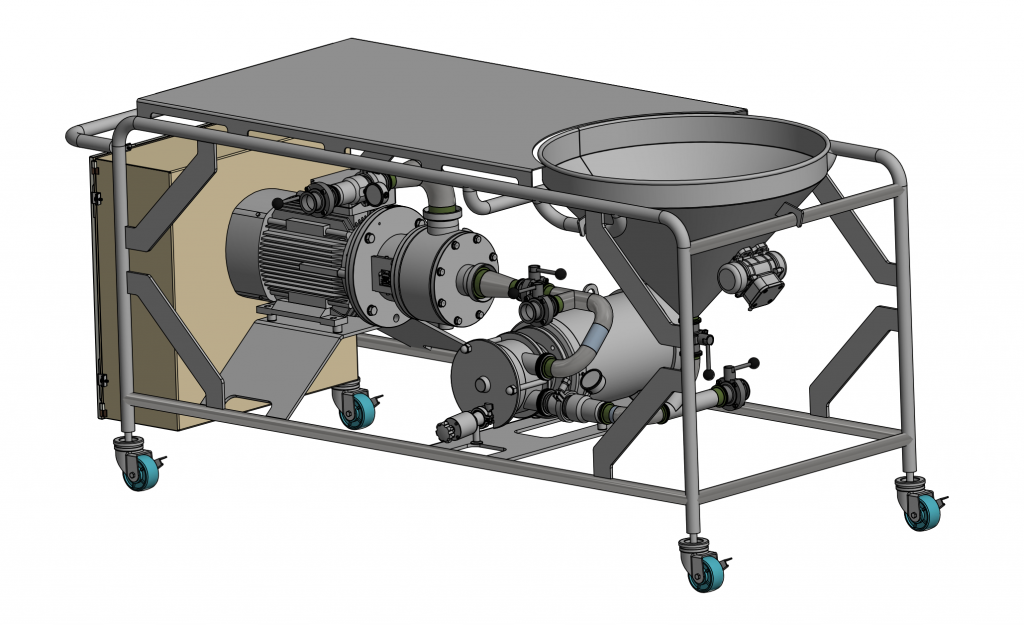

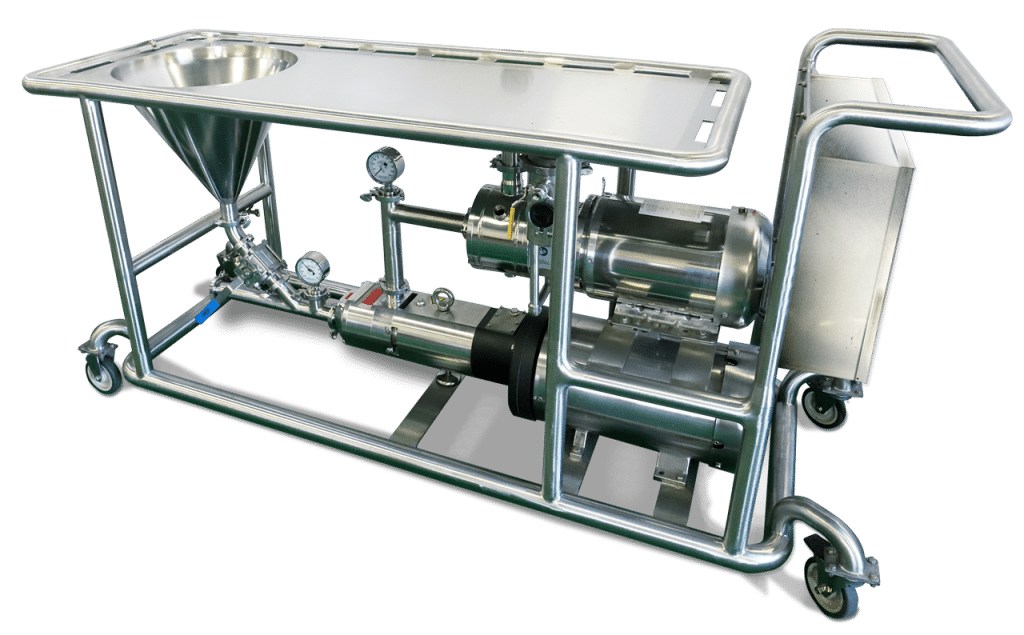

The INFINI-MIX Recirculated Batch Mixer (RBM) uses the H-series mixer in along with our either the TRUE™ Liquid Ring Pump or a Twin Screw Pump as a Powder Induction System. The pump simultaneously draws the fluid out of the vessel and and the powder out of the hopper and then pushes the pre-mix through the mixer. Our mixers get the highest amount of shear in a single pass.

The Liquid Ring option is used for lower viscosity fluids under 2,500 cps while the Twin Screw option is used for higher viscosity fluids.

Using An Inline Mixer in a Continuous Process

Powder induction systems can only be used in a batch-type process where there is a finite amount of product being made. This is where most high shear mixer companies stop.

INFINI-MIX offers a unique, single pass solution for blending multiple solids and liquids. The “Joby-Nator” is a pre-wetter and static mixer solution which accepts multiple direct ingredient streams for continuous mixing. The ingredient streams can be solids and liquids, but a liquid component is always required.

The Joby-Nator is designed to be installed prior to any type of pump, centrifugal or positive displacement. The powders are pre-wetted to make the mixture “pump-able” so it can pushed through the inline mixer. This is unique to INFINI-MIX!

COMMON APPLICATIONS FOR HIGH SHEAR MIXING

Margarine / Droplet Size Reduction

Edible Oils — Oil Degumming & Dispersion of Phosphotides

EXAMPLE

A candy manufacturer wanted to eliminate “fish eyes” from gums that were not fully wetted out. Their strainers downstream were constantly plugged with globules of gums that were never fully hydrated in their batch tank.

Using the “H” Series Homogenizer in a recirculated batch process solved the problem. The contents of the vessel were fully dispersed and produced a smooth, consistent, finished product without clumps or agglomerations. Everything exiting the tank was guaranteed to go through the mixer. This drastically reduced batch times and down time associated with plugged lines.