HOMOGENIZE, EMULSIFY & TRUE SUSPENSIONS

Infini-Mix™ offers a solution for single pass processes or batch processes that require you to homogenize and emulsify or create a true suspension. Most of our competitors offer “batch-type solutions” with a variety of HIGH shear rotor & stator combinations. This means that the mixture must make multiple passes through the work head on the mixer. This could be an inline or an in-tank mixer. But not Infini-Mix™!

Infini-Mix™ has ability to provide a solution for a batch process as well as an inline, single pass process. More importantly, we do not just focus on high shear. We offer the widest range of mixing intensity solutions than ANYONE! We can even simulate manual stirring.

SINGLE PASS PROCESS, High Shear Applications

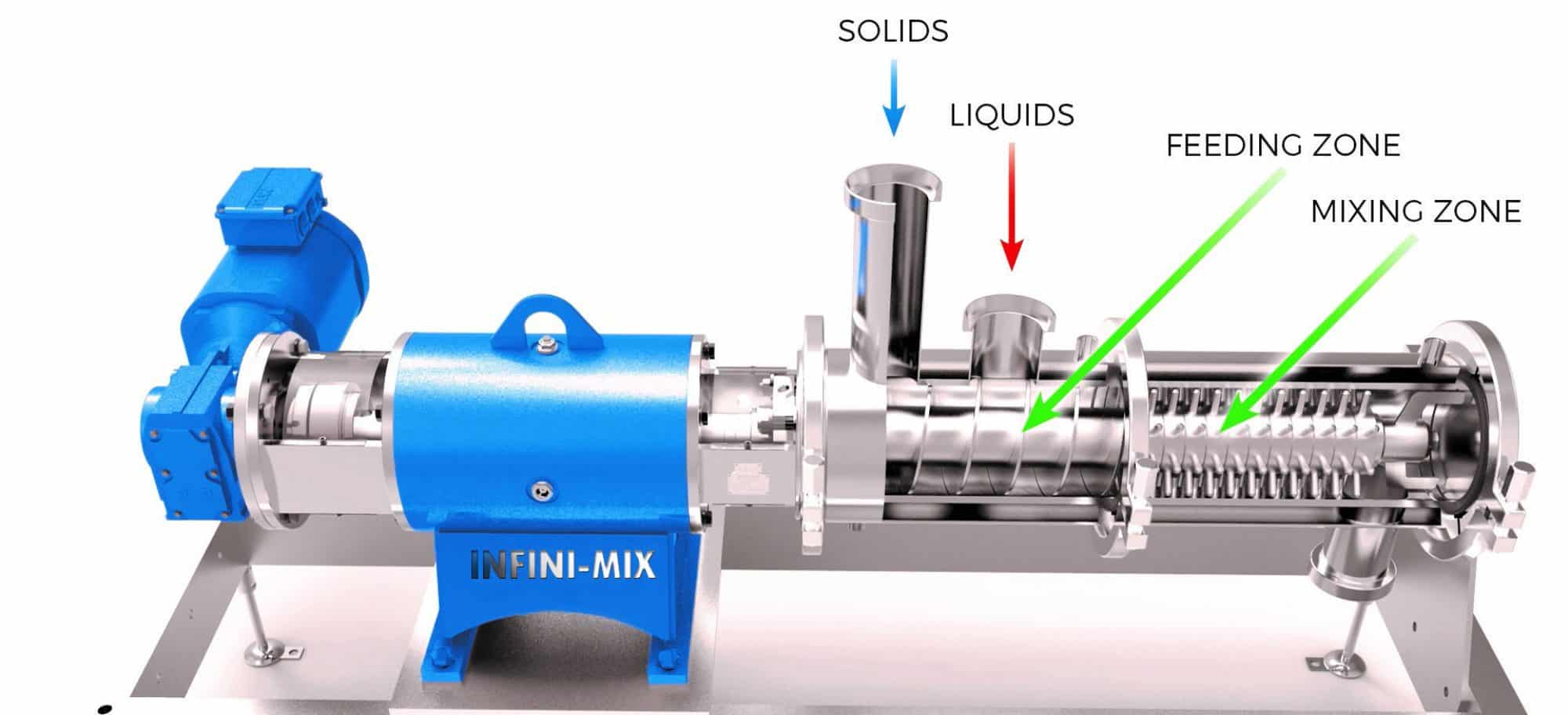

The JOBY-NATOR inline pre-wetting device accepts multiple direct solid and liquid ingredient streams for applications that require high shear to fully hydrate and homogenize in a single pass.

The JOBY-NATOR is a non-vacuum, powder induction device that brings solids and liquids together and then pumps through a shear mixing device. This can be used to create sugar syrups and salt brines in a single pass. It can hydrate even the most hygroscopic gums in a single pass without unnecessarily aerating the product.

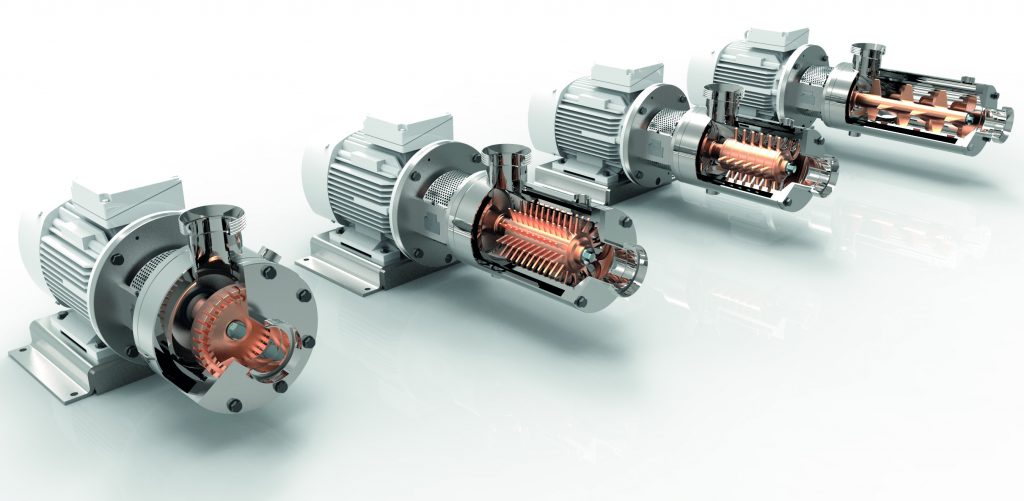

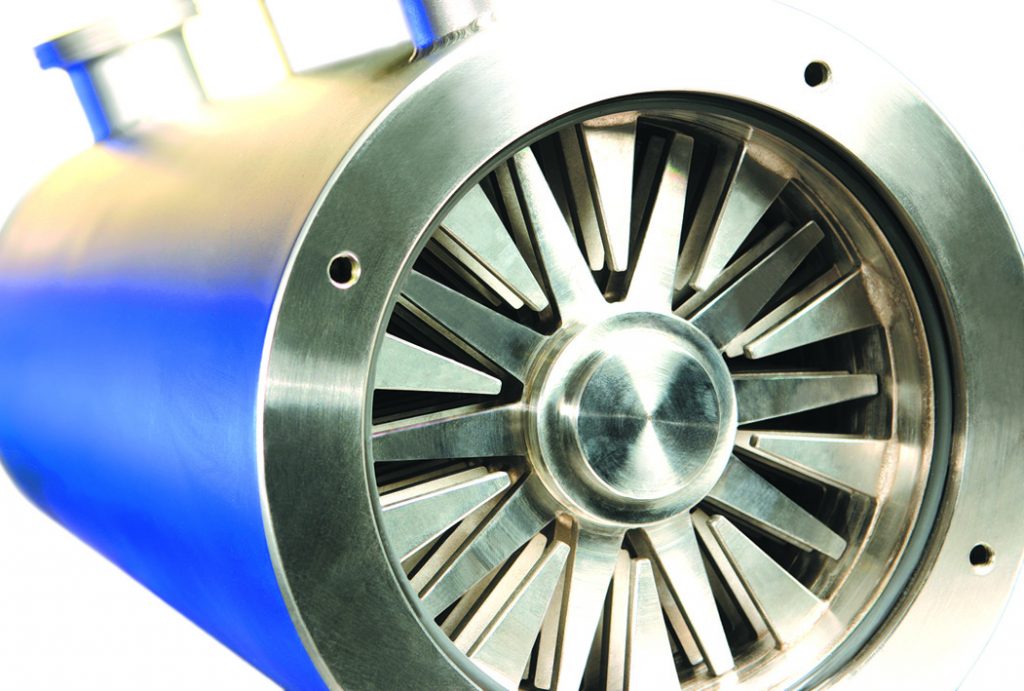

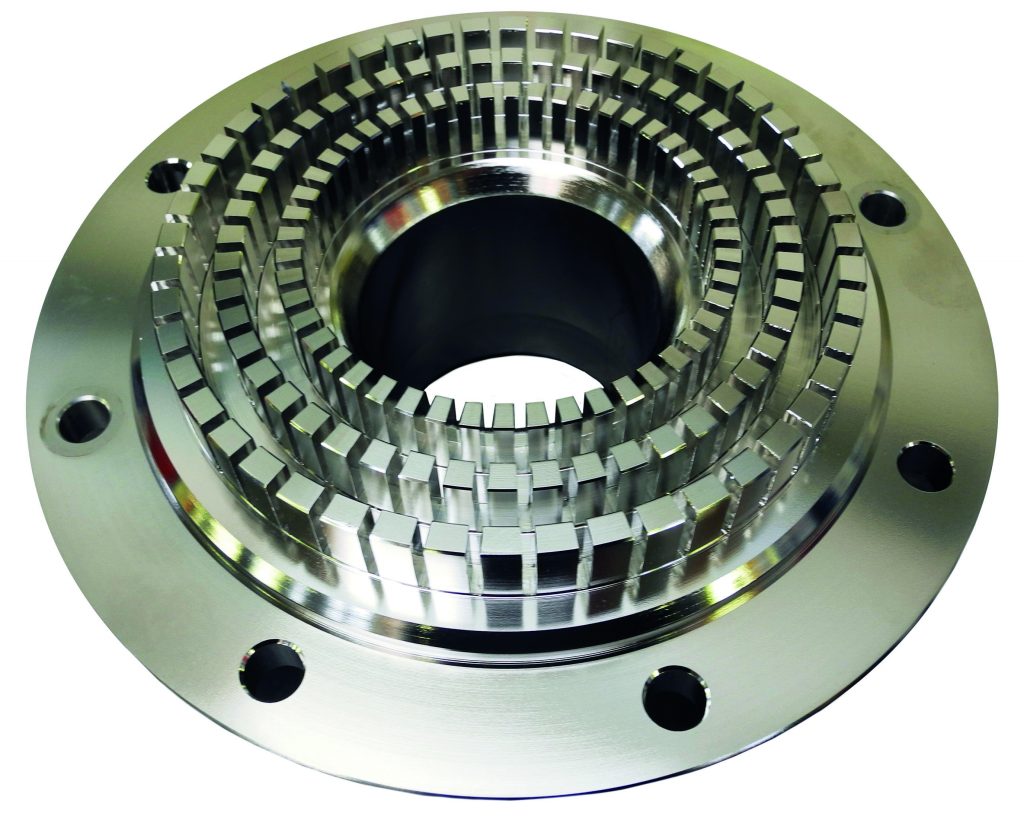

Our “S” Series mixer is our medium shear device and can homogenize and emulsify while imparting more than 3,000+ s-1 of shear on a product. This is more than what most consider high shear.

The use of multiple stages with 2 – 5mm gaps allows for extremely high viscosity fluids, far greater than any other high shear mixer on the market.

Our “H” Series mixer is our highest shear device and can homogenize and emulsify while imparting more than 30,000+ s-1 of shear on a product. This allows us to get <2 micron droplet size on emulsions on a single pass. While many of our competitors try to add pumping capability to their high shear devices, our mixers are designed to MIX. Adding pumping capability takes reduces the amount of energy available for mixing.

Let’s face it, most powder induction systems on the market focus on selling inline mixers. The focus is on selling the rotor / stator device and very little thought is put into getting the powders into the liquid before the mixer. All of these solutions use some kind of vacuum to “suck” the powder into the liquid. This makes controlling the powder feed rate nearly impossible for an accurate, single pass solution and also unnecessarily aerates the product.

Manufacturers of other powder induction systems sacrifice mixing intensity to gain pumping capability. They typically rely on liquid ring centrifugal pumps to create the vacuum to pull the powders into the liquid stream and to provide the motive force for the liquid. These are incredibly inefficient and are limited by viscosity and discharge pressure.