Inline Mixing Solutions

INFINI-MIX is the exclusive brand name for North American Process, Inc.’s INLINE MIXING SOLUTIONS. Unlike most companies that offer inline mixers, INFINI-MIX is the only company to offer virtually all types of inline mixers: LIQUID-LIQUID, SOLID-LIQUID and GAS-LIQUID. Additionally, INFINI-MIX is the only company to offer the widest range of MIXING INTENSITIES, from being delicate and being able to simulate manual stirring up to high shear homogenizing and emulsifying.

Let’s face it, most inline mixer companies focus on powder induction systems. Their focus is on selling the rotor / stator device and very little thought is put into getting the powders/solids into the liquid before the mixer. All of these solutions use some kind of vacuum to “suck” the powder into the liquid. This makes controlling the powder feed rates nearly impossible for an accurate, single pass solution, especially with a wide range of products. This also unnecessarily aerates the product. These mixers are focused on more intensive mixing solutions without offering ways to mix more delicate products like fruit fillings or prepared foods or other shear sensitive liquids. This is a “one size fits all” mentality.

Here is how INFINI-MIX is different...

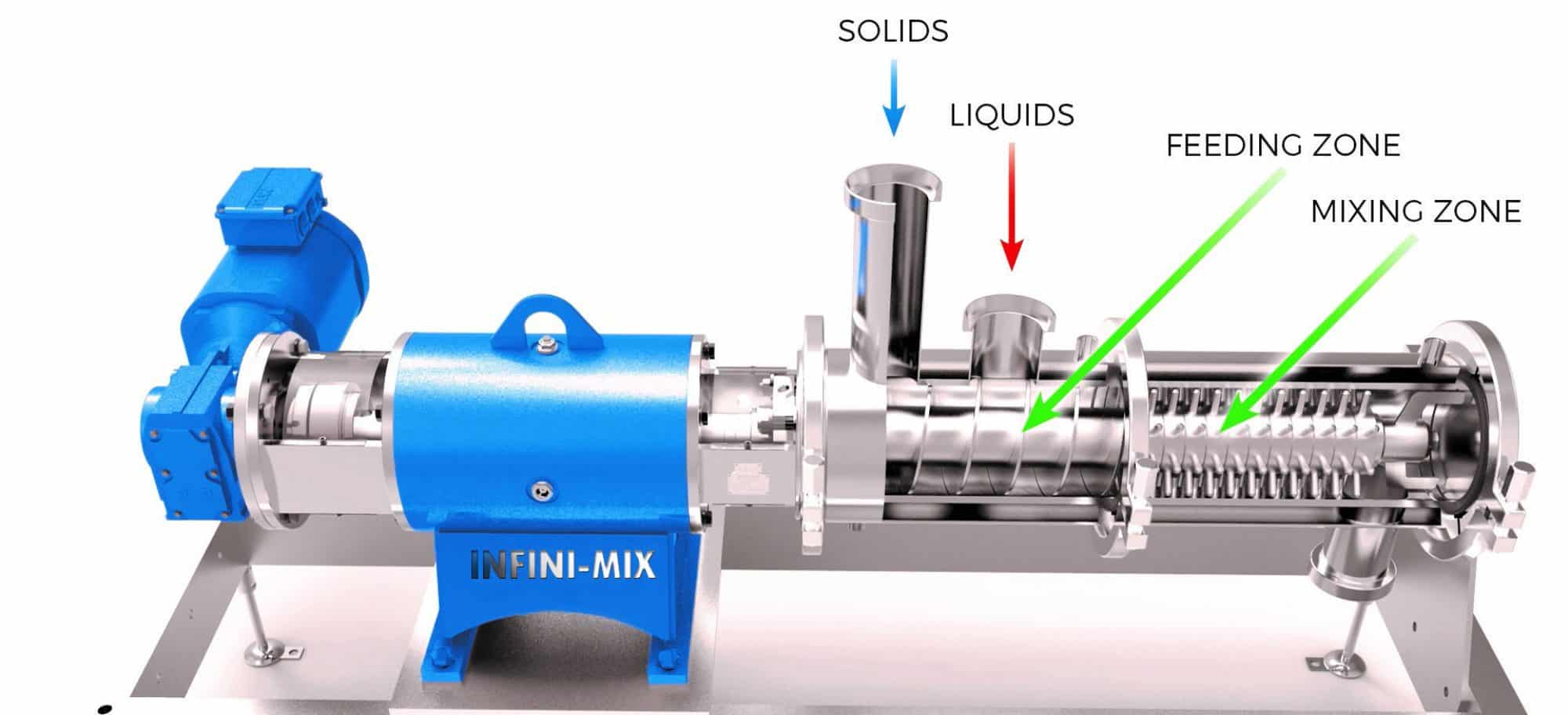

SOLID - LIQUID MIXING

Delicately blend macaroni and cheese on-demand. Accurately dose large solids like nuts and “crispies” into chocolate without adding heat or hurting the crystal structures in the chocolate. Add sprinkles and chocolate pieces to an aerated fat mass, filling or frosting without affecting the density or foam structure. Add multiple solid inclusions and liquid flavorings into ice cream simultaneously with a single mixer in a single pass.

For the more vigorous mixing applications, hydrate gums and starches in a single pass without a single fisheye and without aerating the product. We do not use VACUUM to draw powder into our mixers—we use GRAVITY! This allows for better control for single pass solutions and lessens the opportunity for aerating your product.

LIQUID - LIQUID MIXING

Blend fruit prep into white mass yogurt and switch from flavor to flavor within minutes with little to no product loss. Add a pepper and chorizo slurry to a queso dip. Mix spices and vegetables into sour cream and yogurt-based dips. Dose minute amounts of fragrances or active ingredients into a detergents and lotions without having to use a batch tank.

Imagine the cost savings of being able to make a more standard base product and then injecting these various differentiating additives at the point of use instead of dirtying another tank!

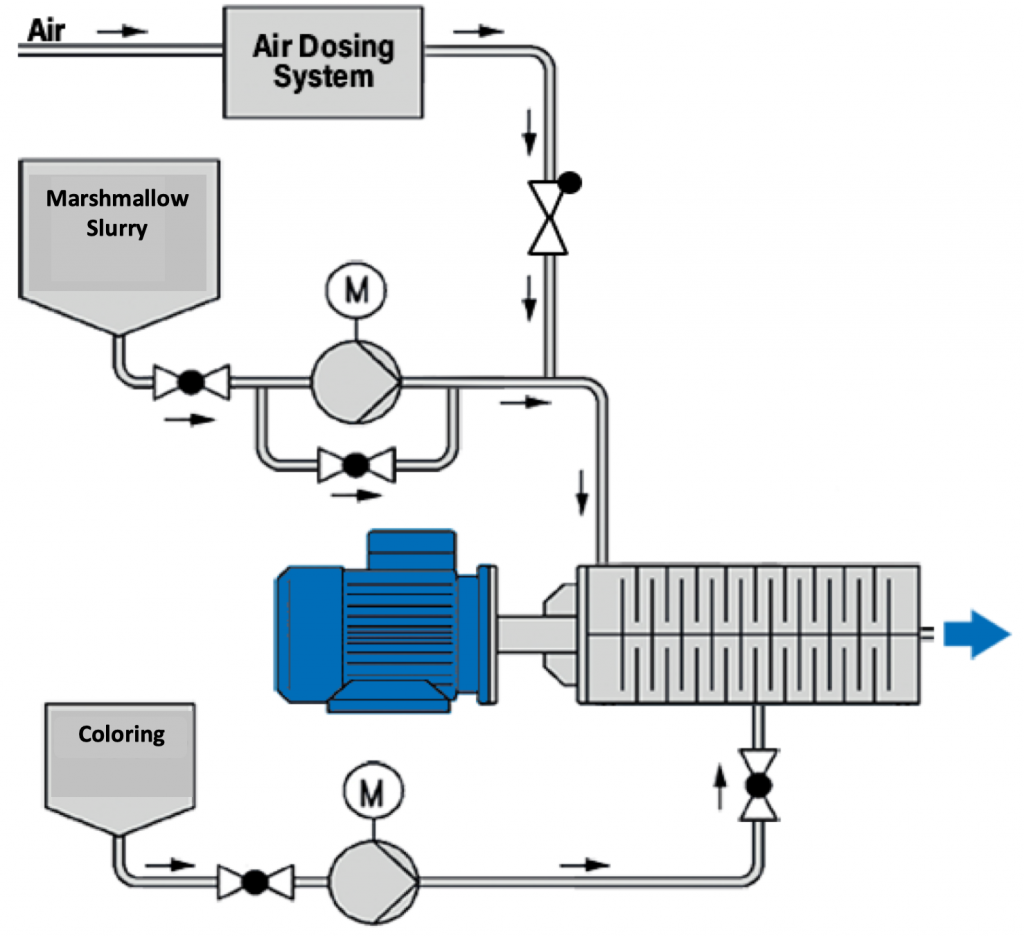

GAS - LIQUID MIXING

Inject and disperse steam to thoroughly cook cheese sauces or prepared foods for extended periods of time without burn-on or fouling. Our dynamic mixers use 100% of the thermal properties of the steam. This is far more efficient than simple static steam injectors.

Aerate fat masses with CO2, O2 and N2 at lower rotational speeds than the competition. This better protects fats and generates far less heat.

From Simulating Manual Stirring to Homogenizing & Emulsifying

Hydrate Gums without Aerating & Never a “Fisheye”

Maintain Large Solids

Viscosities in Excess of 10,000,000cps

Trial Fleet à Pilot Plant Testing

Late Stage Differentiation Efficiencies

INFINI-MIX is the ONLY Company you need for all of your INLINE Mixing Solutions. We are the SINGLE-PASS Mixing Specialists.