Liquid-Liquid Mixers

INFINI-MIX™ offers the widest range of dynamic, inline mixers for blending multiple streams of liquids simultaneously. Our Liquid-Liquid mixers range in mixing intensity from LOW SHEAR to simulate manual stirring, all the way up to HIGH SHEAR homogenizing and emulsifying.

Why "IN-LINE" Over "IN-TANK"?

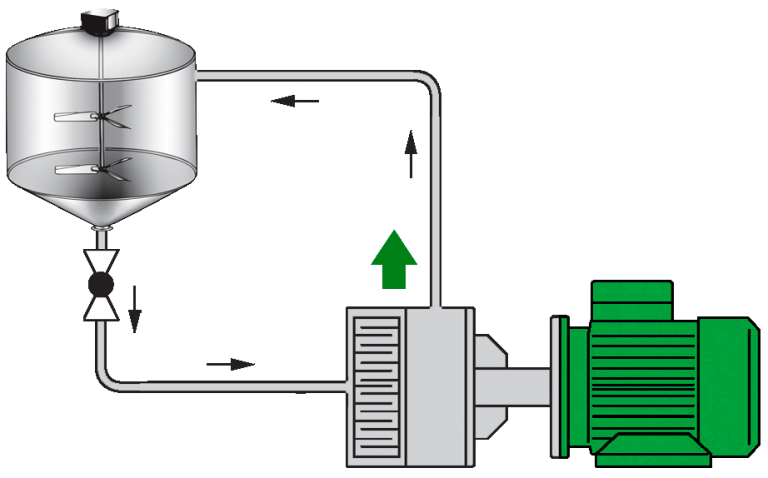

INFINI-MIX™ only does Dynamic, INLINE MIXERS! An inline mixer is located outside of a tank (or group of tanks). The contents of the tank are recirculated through the mixer and back to the top of the tank until the product is homogenous. Everything exiting the tank is guaranteed to run through the mixer. This eliminates the need for strainers downstream to catch agglomerates and “clumps” of unmixed powders.

An “IN-TANK MIXER”, or batch mixer, is a tank-mounted mixer. Though often less expensive than most “INLINE MIXERS”, batch mixers are typically sized for a specific application or range of applications on a specific tank. Once installed, batch mixers can be difficult to move around from tank to tank.

An INLINE MIXER can be put on a cart and wheeled from tank to tank easily. It can also service multiple tanks through simple flow panels and valve manifolds. There is increased flexibility with an inline, mixing solution. ASK OUR EXPERT!

Why "Dynamic" Dominates "STATIC" Mixing

Infini-Mix™ only does DYNAMIC Mixers! “Dynamic” means that there is always a rotating element that is creating the mixing energy. Varying the rotor / stator combinations as well as the tip speed and clearances of the rotor allow us to dial-in the precise mixing result.

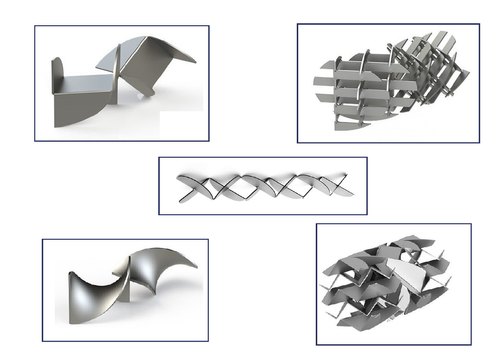

Though some are standard “cookie cutter” inserts, most “STATIC” mixers are custom fabricated for an application and are fitted inside a length of pipe. Static mixers have no moving parts. The insert is cut, bent and twisted in specific, engineered patterns in order to create the desired mixing result. The geometry can be simple or complex depending upon the complexity of the application. Most importantly, they are sized for a specific mixing result for a specific application at a given pipe velocity. They are limited to Liquid-Liquid or Liquid-Gas applications.

Because static mixers act as “obstacle” courses inside the pipe, they can create high pressure drops and also be difficult to CIP. All INFINI-MIX dynamic mixers are fully CIP-able and have little pressure drop during process or CIP. Additionally, any given mixer can cover a wider range of applications and mixing intensities simply by varying the speed. Our wide variety of rotor & stator combinations can ensure thorough mixing in Liquid-Liquid, Solid-Liquid and Liquid-Gas applications. ASK OUR EXPERT!