LOTIONS & CREAMS

SOLUTION #1

HIGH SHEAR, HIGH VISCOSITY DISPERSIONS

Active ingredients, emulsifiers and thickening agents commonly require high shear mixing and dispersion during the manufacturing of lotions, creams and ointments. Intense, vigorous mixing is required to eliminate clumps and agglomerations.

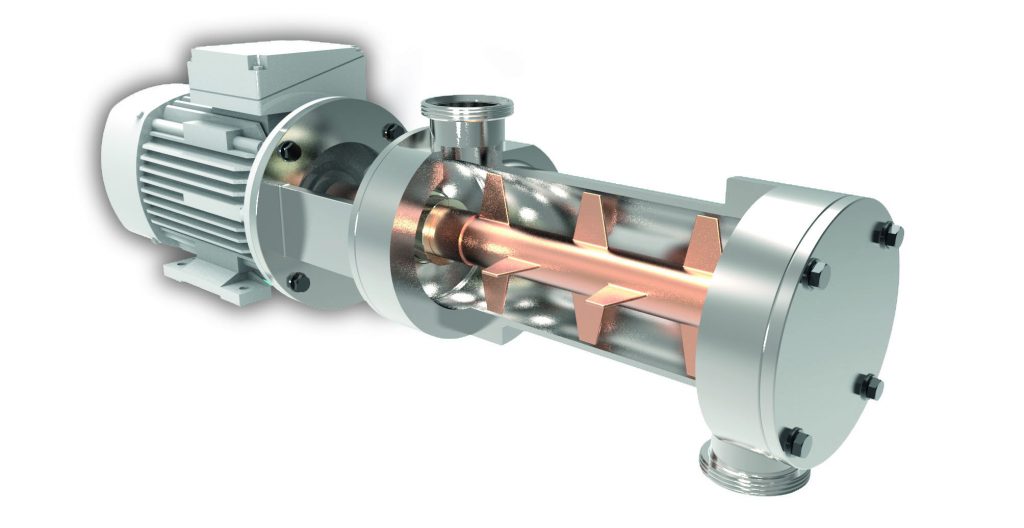

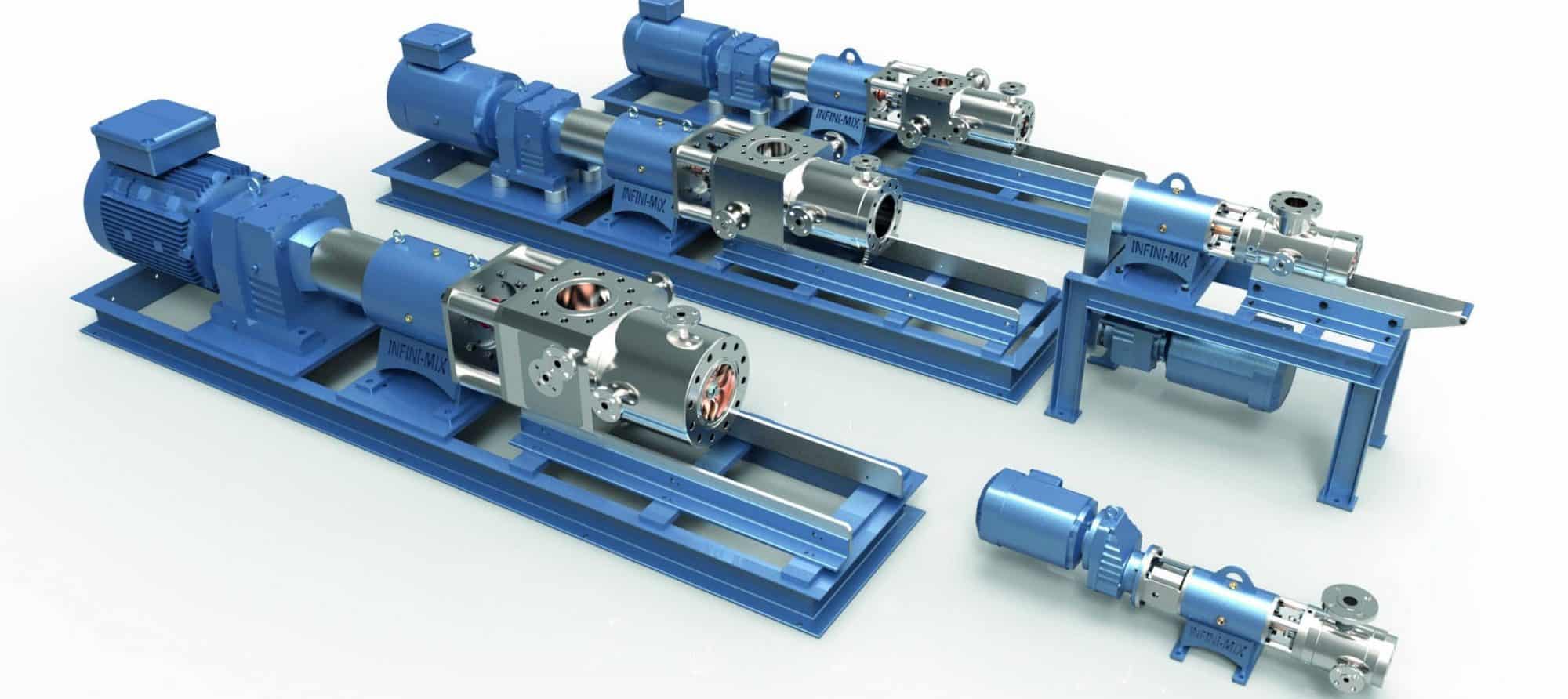

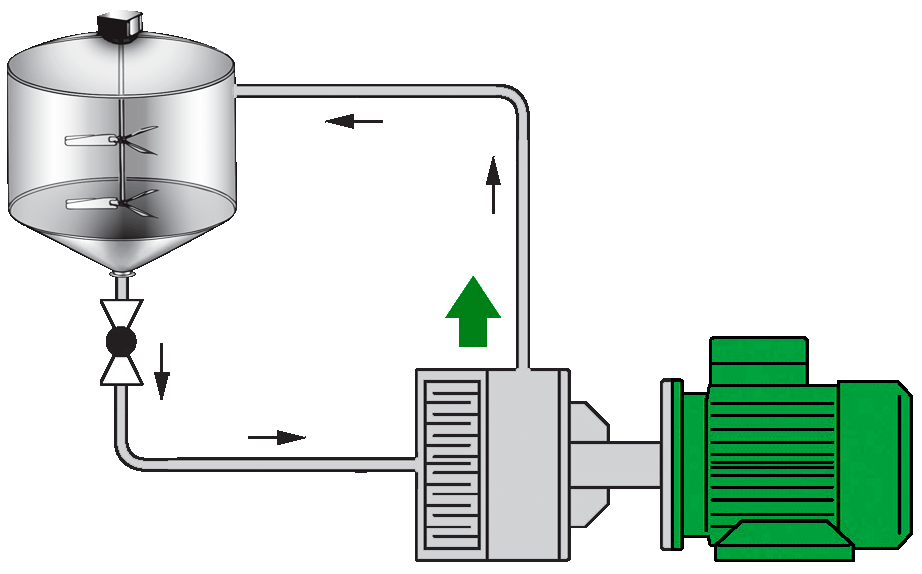

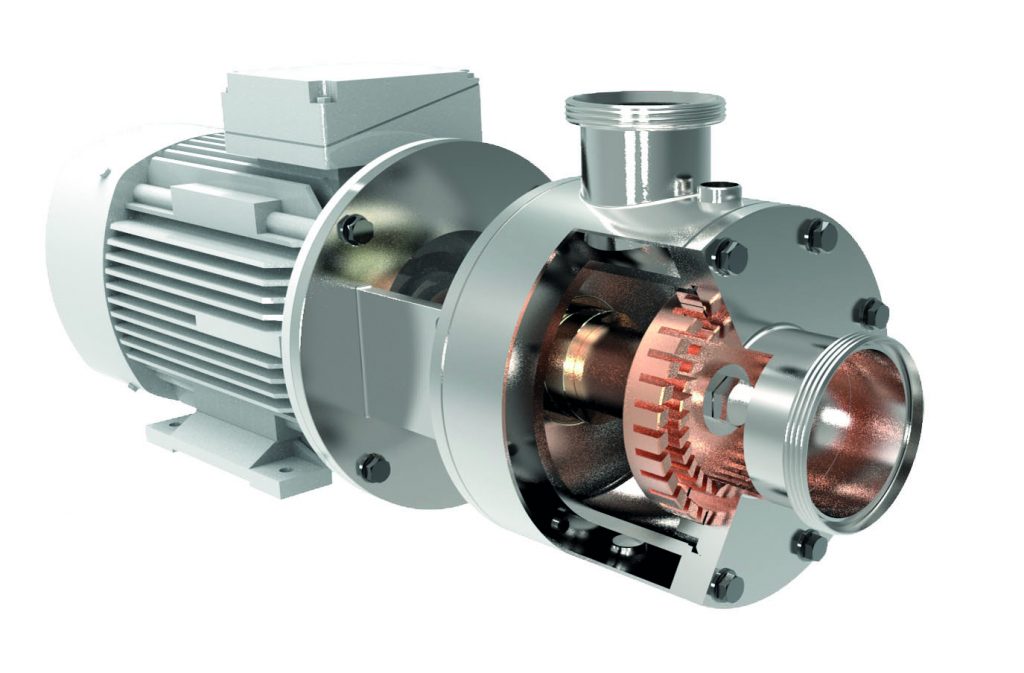

The Infini-MixTM H series homogenizer and emulsifier is ideal for high shear mixing and dispersion of these difficult ingredients. Used in a recirculated batch process ensures that all products are thoroughly mixed and the end product is homogenous.

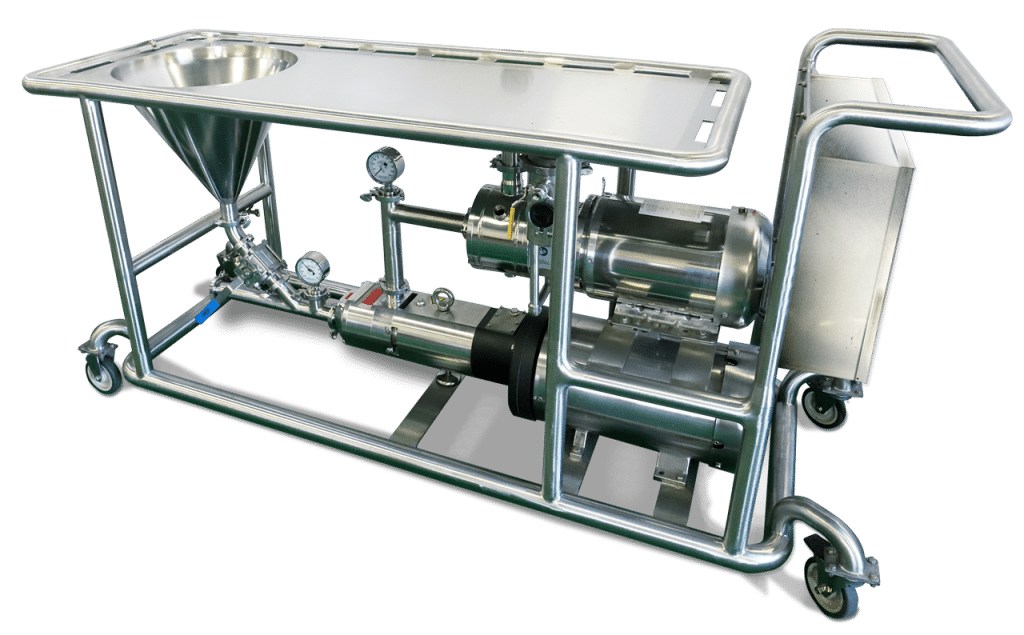

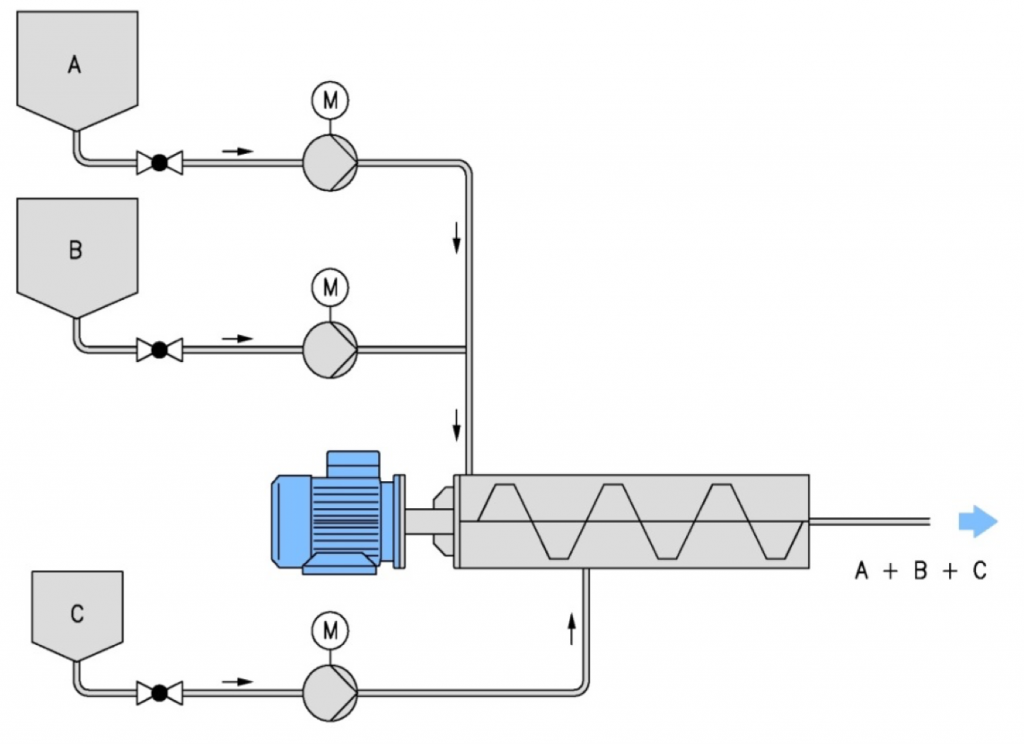

The Infini-Mix RBM systems can be used to suck all of the powders into the liquid stream at ground level. We use both liquid ring and twin screw pump technologies to draw the powders into the liquid stream, regardless of the viscosity of the motive fluid. This is why the Infini-Mix RBM is uniquely qualified for these applications.

SOLUTION #2

Late Stage Differentiation of Lotions, Creams & Ointments

The Infini-MixTM N series mixer simulates manual stirring. It can delicately blend minor differentiating ingredients without destroying the form and structure of the product or cause foaming. When it is time to switch to a different recipe, simply clean the mixer and you are on to the next product. The only product lost is what is in the mixer. This is a huge cost savings!

It is not uncommon for manufacturers to have multiple variations of the same base product. A fragrance, a specific active ingredient or even an exfoliant may be the only difference from one formula to another. Some of these differentiating ingredients can be added at the end of the process, making the change from formula to formula quicker and less costly.