MAINTAIN SOLIDS INTEGRITY

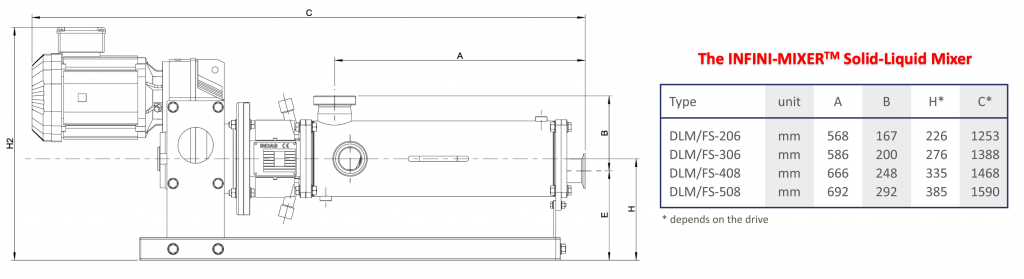

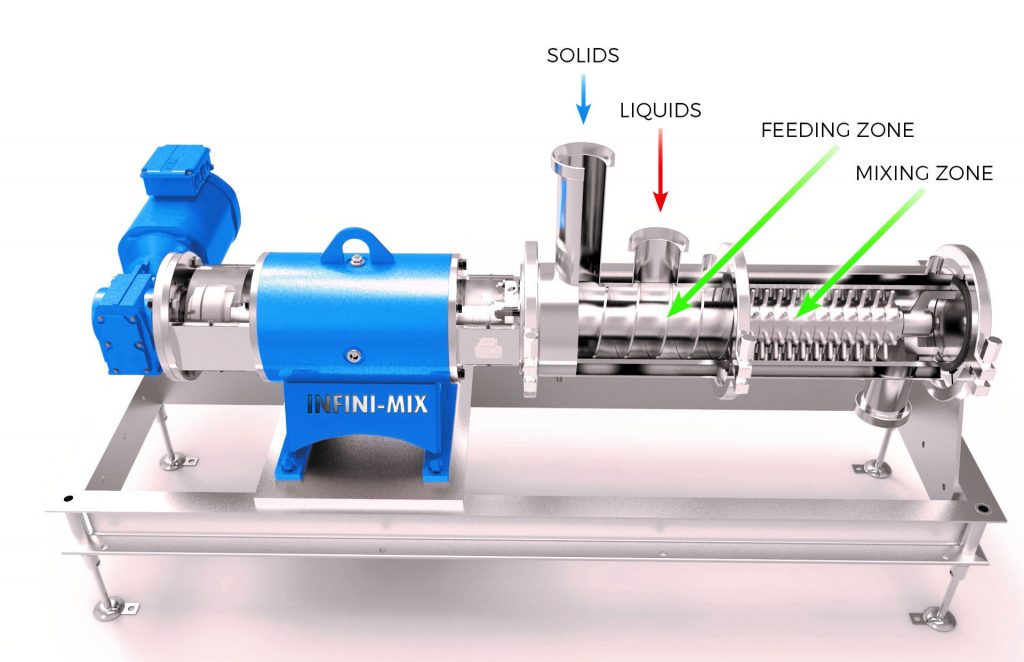

The Infinite Ingredient Mixer, or Infini-MixerTM, gently blends multiple solid and liquid ingredient streams thoroughly while being able to maintain solids integrity. Each ingredient stream is metered into the mixing chamber at the appropriate ratio to ensure single pass accuracy. Ideal for blending whole fruit into yogurt or mixing the complete list of ingredients for Potato Salad, the combination of the feeding and mixing chambers produce a consistent, repeatable finished product with little to no product damage or loss of integrity.

The Infini-MixerTM is ideal for Late Stage Differentiation (or “End of Pipe”) applications where a final ingredient (or set of ingredients), can be added to the primary liquid at the end of the process or at the filler. These final ingredients can be delicate inclusions, fragrances, coloring or virtually anything.

EXAMPLE

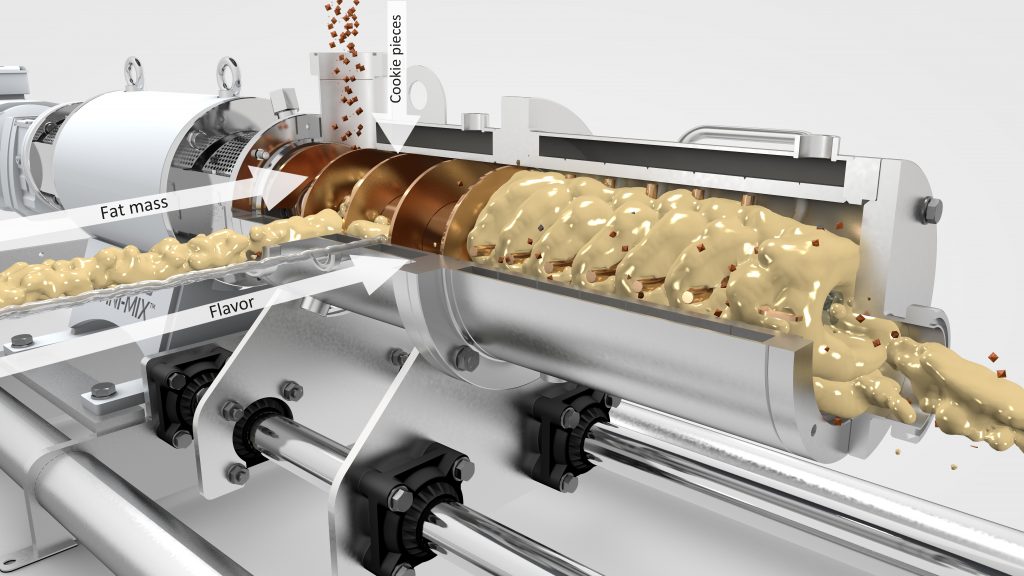

A chocolate candy bar manufactures a variety of milk chocolate bars. Some are plain milk chocolate and others have various inclusions like nuts, raisins, “crisps” or even cookie pieces.

Instead of making a separate batch with each inclusion and having to clean the tank in between products, the manufacturer can make the same chocolate all day long and use a single Infini-MixerTM at the end of the process to add the final differentiating ingredient just prior to packaging.

When the manufacturer wants to switch from one product to another, they only need to clean the mixer. This saves a tremendous amount of time on product changes and cost related to cleaning. More importantly, the was able to continue to make a high quality chocolate bar and maintain the integrity of the large solids.

COMMON APPLICATIONS FOR MAINTAINING SOLIDS INTEGRITY