MOST POWDER INDUCTION SYSTEMS SUCK!

What is INDUCTION? The dictionary defines it as the process of introducing. For the sake of our conversation, we are talking about “the process of introducing and/or incorporating powders into liquid.

As companies have tried to process their recipes faster while reducing labor and injuries related to dumping bags of powder ingredients into the top of a batching tank, manufacturers of mixers have tried to make “powder induction” systems that can pull the powders into the liquid at ground level.

The most common powder induction systems on the market suck! They have to suck to work. They are trying to pull powders into a liquid stream and push them into a pressurized line. The only way to do this is to create a vacuum of some kind. Though it is falsely implied, INDUCTION reliability is being correlated to SUCTION capability.

Though the text book definition for powder induction says nothing about using vacuum, most customers I speak to think all powder induction systems have to use vacuum. Most of these “off-the-shelf” systems use one of two methods.

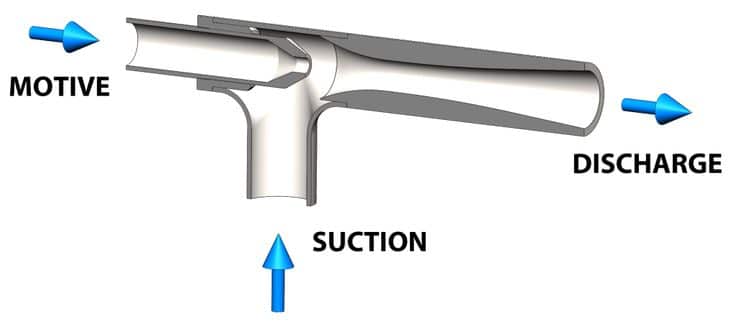

The eductor method is the least expensive. It is where a liquid stream is maintained at a specified pressure and velocity across an orifice. This creates a Venturi effect which then sucks the powder into the stream of liquid.

The more common systems use pumps with high suction capability to suck the powders into a liquid stream and then push the pre-wetted powder through a rotor & stator device to disperse the powder.

We have done these types of “powder induction” systems as well. We have used eductors and liquid ring pumps and twin screw pumps on these systems. They all have their benefits but they also have the same short comings and limited flexibility as a single pass solution, especially as the base liquid gets above 2500 cps.

All of these systems are relying on some type of vacuum to “suck” the powders into a liquid stream. While sucking in the powder you are also sucking in a high volume of air into the product. This can cause foaming and even short fills if the product is not ultimately deaerated or the air is somehow drawn or purged out of the mixture before packaging.

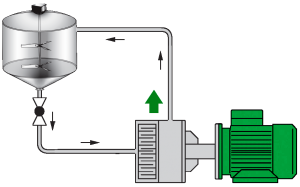

Secondly, these systems may be able to disperse the powders into the liquid in a single pass, but this DOES NOT make the mixture homogeneous in a single pass. Neither the powder feed nor the liquid feed are being controlled to the appropriate ratios in any meaningful or verifiable way. The powder is sucked into the liquid very quickly so it is only dispersed into a small amount of the total liquid in the batch. Therefore, after all of the powders are incorporated into the batch, the operator must continually recirculate the mixture until all of the contents in the vessel are truly homogeneous.

So even though the powder is fully dispersed into the liquid quickly, you will still need multiple passes through the system. The rule of thumb is that it takes turning over the full contents of the vessel a minimum of 3 times before the batch is deemed homogeneous. So a 1000-gallon batch must run through the mixer 3 times. A 100-gallon powder induction system may be able to incorporate all of the powders in a few minutes. However, they would need to recirculate for 30 additional minutes after all ingredients are incorporated before you could safely say that the batch is homogeneous and consistent.

Additionally, the biggest limitation to these systems is that they are incredibly inefficient on more viscous products. The thicker the liquid becomes, the more difficult and timing consuming it is to continue to draw powders into the liquid.

You don’t have to suck anymore!

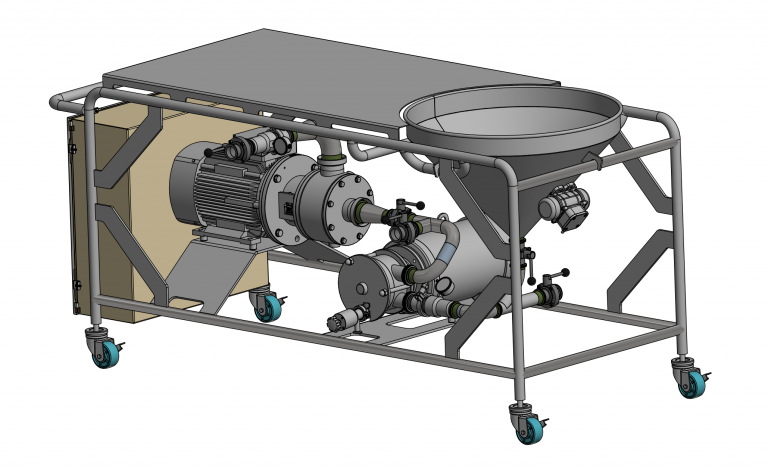

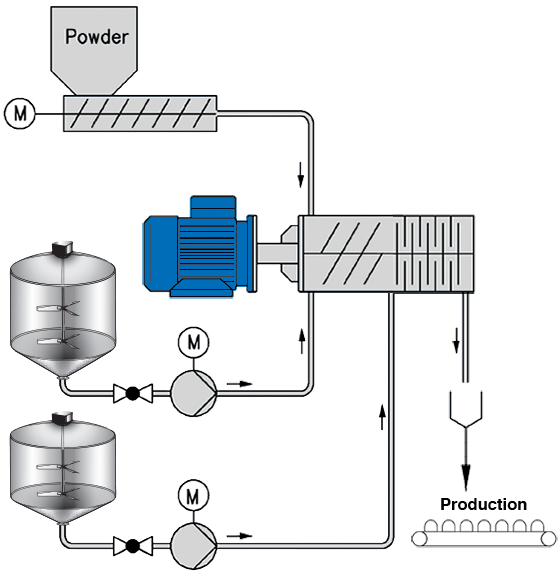

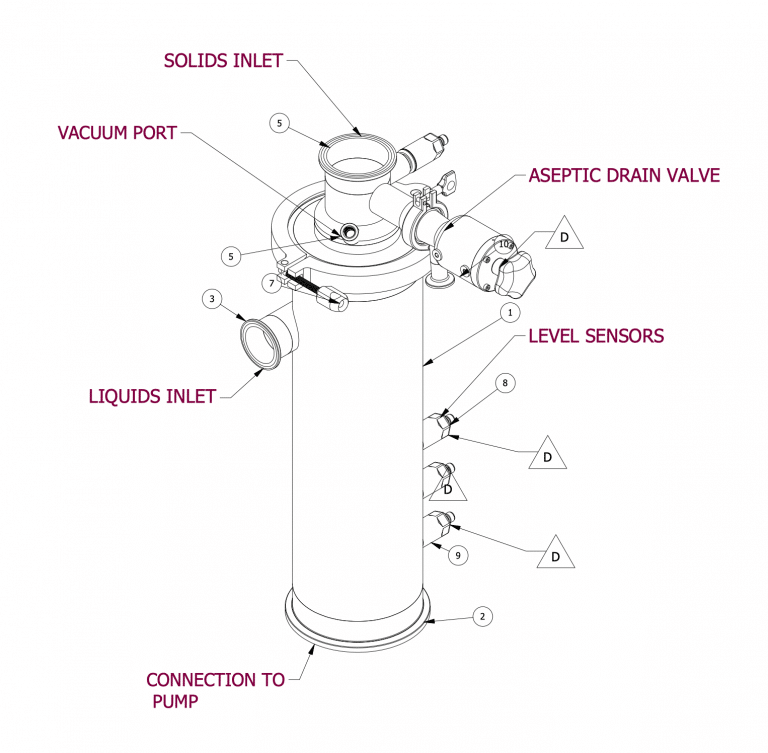

Our focus at INFINI-MIX is to develop truly continuous, single pass mixing solutions. We don’t use vacuum, we use gravity!

The liquid flow to our systems is accurately controlled with valves and instrumentation. The powder feed is controlled by highly accurate loss-in-weight feeders so that the liquids and solids come together in the mixer at the appropriate ratio at the very beginning. The on-board controls allow for the solids feed to modulate with any change in the liquid flowrate. The discharge of the mixer is a finished product and requires no additional mixing energy and does not unnecessarily aerate your product. Our two most common “powder induction” systems are our INFINI-MIXER and the JOBY-NATOR.

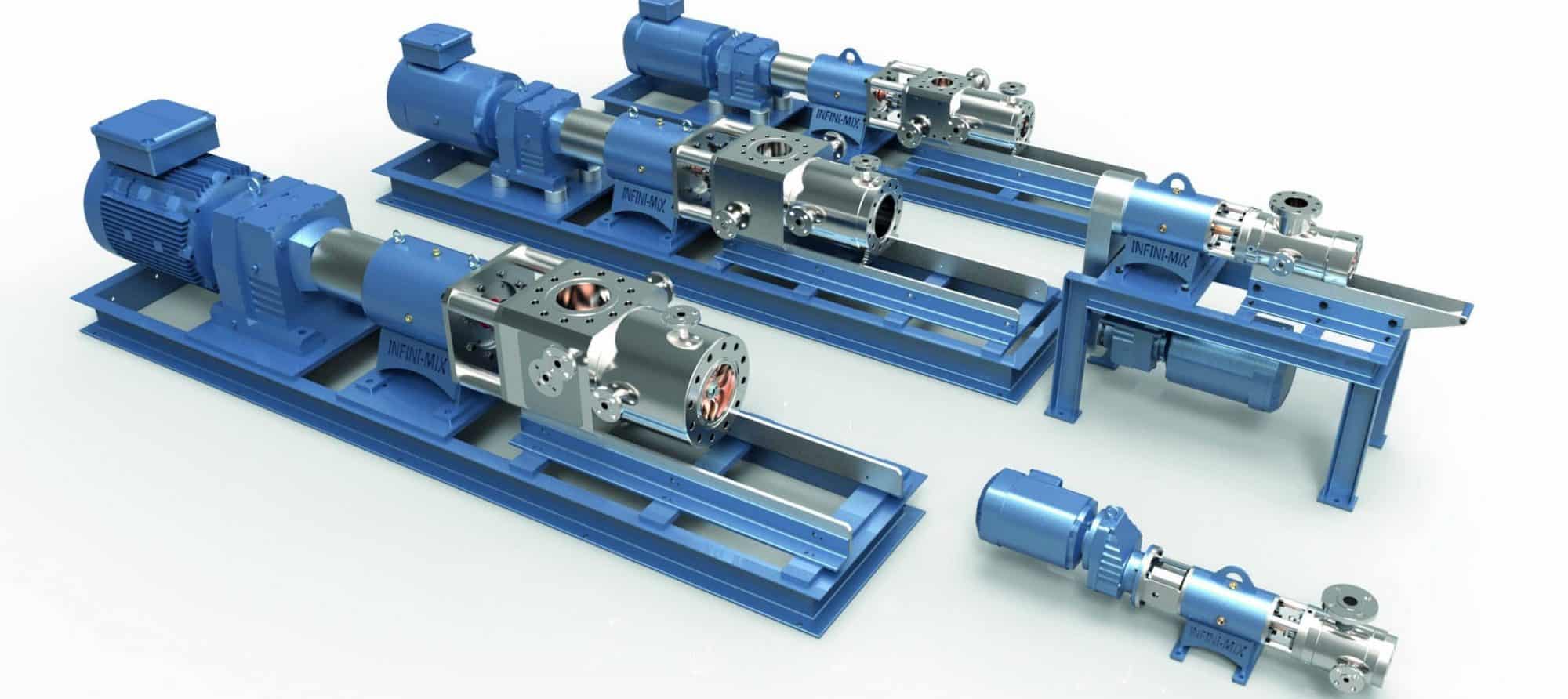

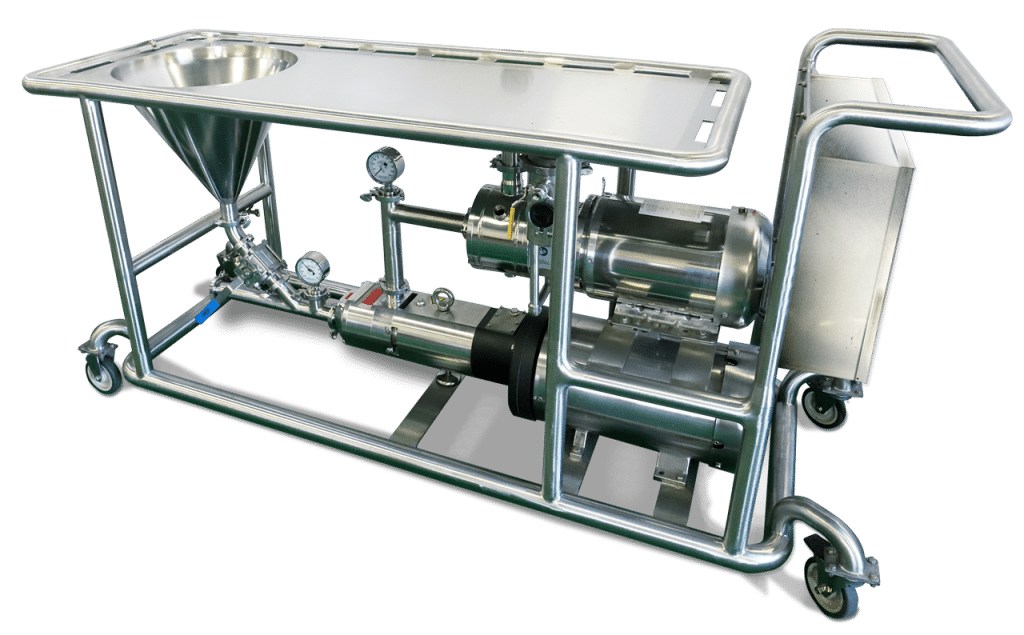

The INFINI-MIXER is a low rotational speed device that can be used on fine powders as well as large inclusions and soft solids. The base unit is designed for medium to high viscosity liquids with up to 50% solids. Nut & seed butters, batters & doughs, prepared foods & confectionery products are all ideal applications for this SOLID-LIQUID mixer. Some configurations allow for up to 92% solids as in the case for coating oats and grains for granola bars and cereals. With a wide variety of mixing elements, the INFINI-MIXER can be used for a wide range of applications requiring from low to moderate levels of mixing energy.

The JOBY-NATOR is a high rotational speed device that is primarily for low to medium viscosity products and can generate moderate to extremely high levels of mixing energy. Creating sugar syrups & brines on the fly as well as hydrating gums & starches in a single pass are all common applications for this method. The powders and liquids are metered into the JOBY-NATOR so you get a truly homogenous product on the discharge.

This is how continuous, single pass mixing systems work. In many cases, no vessels are required because the ingredients are coming together inside the mixer. This is a tremendous savings in space and labor. These systems can be used for small runs up to recipes that need to run for days. All of our solutions are capable of being cleaned in place.

INFINI-MIX single pass solutions can be developed for nearly any type of application: LIQUID-LIQUID, SOLID-LIQUID and LIQUID-GAS. They can also be designed to create any level of mixing intensity from simulating manual stirring up to high shear homogenization and true suspensions.

Contact us today to discuss your application.