PEANUT BUTTER

SOLUTION #1

Adding "CRUNCHIES" & Other Inclusions

Until recently, peanut butter manufacturers used one of two methods for adding “crunchies”, or chopped peanuts, to their creamy peanut butter. The most common way was to use the old ice cream varigate feeders. These were only capable of adding one inclusion at a time and very heavy on spare parts usage and maintenance.

The other option was to have additional vacuum vessel and add the chopped peanuts into the top and let the batch mixer do its thing. This took up a good deal of production floor space and the agitation was either insufficient for thorough mixing or negatively affected the product integrity. The INFINI-MIXERTM solved these issues.

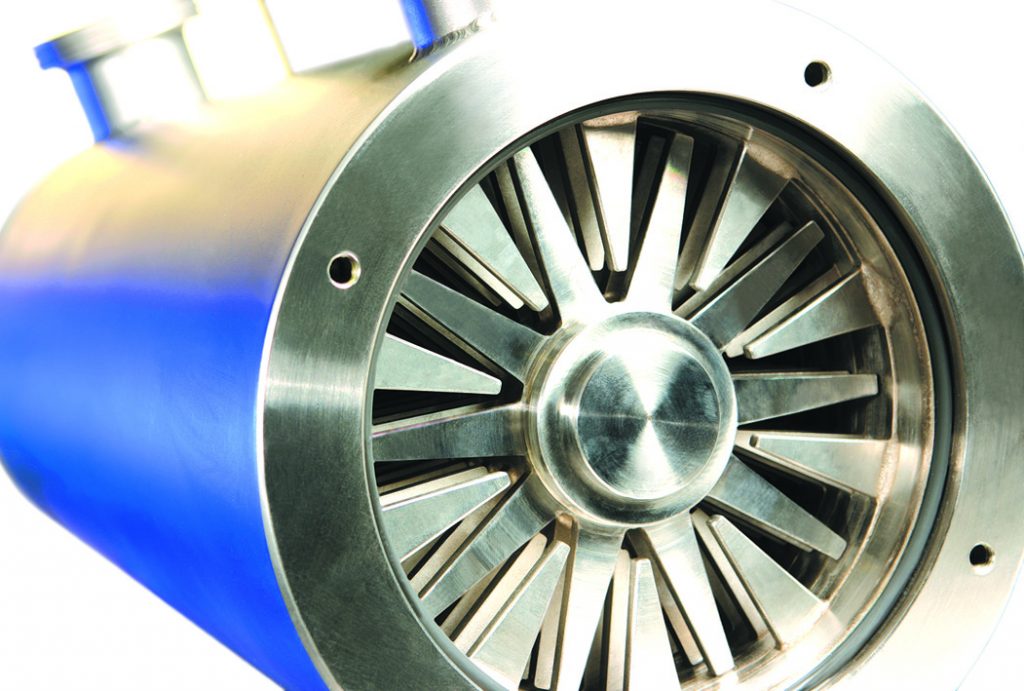

The Infini-MixerTM Continuous Solid-Liquid Mixer utilizes a small footprint and delicately blends chopped peanuts, chocolate chips and raisins into peanut butter while maintaining the highest level of product integrity. Capable of running over 25,000 lbs./hour, simply meter the peanut butter and the solids directly into the Infini-MixerTM for a consistent product every time.

SOLUTION #2

Whipped Peanut Butter - Product Aeration

Whipped peanut butter is becoming more and more popular. Parents love it because you can take cold, whipped peanut butter and spread it on a plain piece of bread without tearing the bread. Kids love it because it is typically extra sweetened with honey. But manufacturers love it because it is 25% nitrogen by volume. They are selling less product for a premium!

Peanut Butter manufacturers can meter their peanut butter and nitrogen directly into the Infini-Mix S-LG mixer to disperse the nitrogen throughly to aerate the product. Additional ingredient ports can be added for honey or molasses or any other sweetener.

Best of all, the S-LG Liquid-Gas mixer comes standard with a jacketed mixing chamber which allows you to control the tempering of the product so aeration is not lost after cooling.