Solid-Liquid Mixers

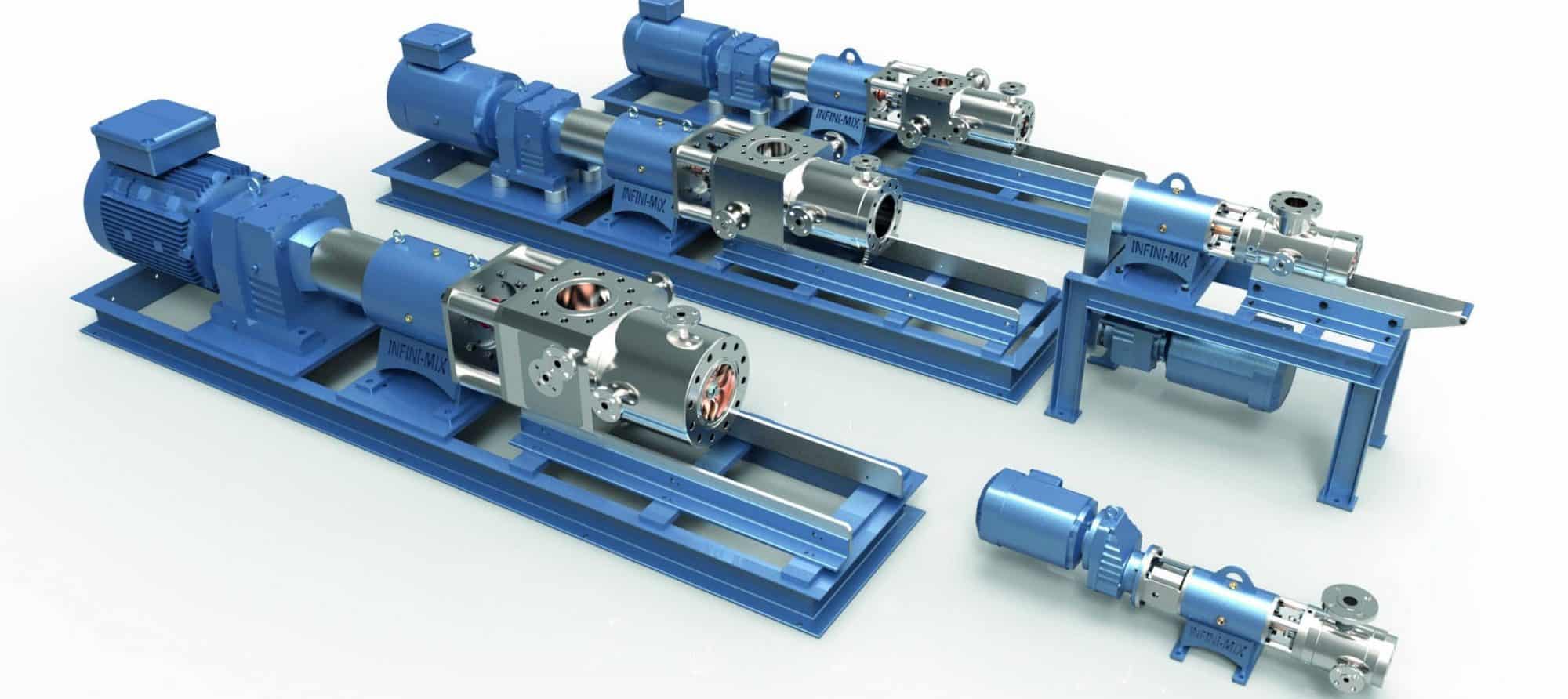

Infini-Mix™ Solid Liquid Mixers can be designed for any level of mixing intensity for a Single Pass, Continuous Process or for a Batch Process.

Most of our competitors offer “batch-type solutions” with a variety of HIGH shear rotor & stator combinations. This means that the mixture must make multiple passes through the work head on the mixer. This could be an “inline” or an “in-tank” mixer. But not Infini-Mix™!

The Infini-Mix™ Solid Liquid offering far surpasses current market competition. From delicate handling, to simulate manual stirring, up to high shear homogenizing & emulsifying, Infini-Mix™ offers a solution for both batch or continuous, single pass processes.

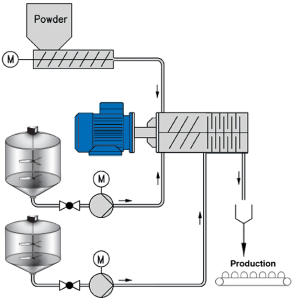

Single Pass, Continuous Process

The Infini-MixTM Solid Liquid offering far surpasses current market competition. From delicate handling, to simulate manual stirring, up to high shear homogenizing & emulsifying, Infini-MixTM offers a solution for both batch or continuous, single pass processes.

All SINGLE PASS process solutions begin with the INFINI-MIXER™. The discharge is then pumped through any of our inline mixers for the desired mixing result.

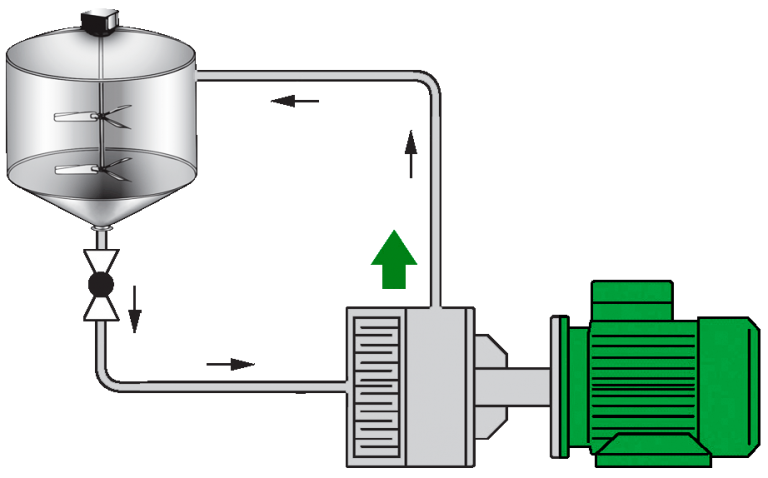

Multiple Pass, Batch Process

Solid-Liquid Mixers for Batch Processes can be designed from being delicate to maintain product integrity up to high shear homogenizing and emulsifying. Infini-MixTM specializes in INLINE mixing solution, not IN-TANK. Our wide range of mixing solutions allow us to dial-in the precise level of mixing intensity as you recirculate you batch through the mixer.

Used in conjunction with a liquid ring or a twin screw pump, we can draw the solids into the liquid stream and push the pre-mix through any of our inline mixers for the desired mixing result.

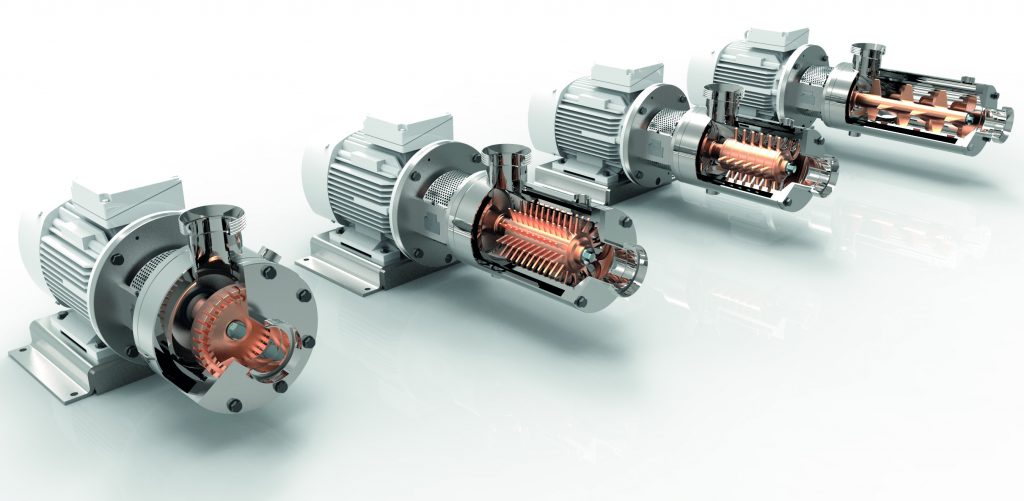

Whether you have a SINGLE PASS, CONTINUOUS PROCESS or a BATCH PROCESS, any one of our mixers can be used to dial in the desired mixing result.

The M, P, S and H series mixers are unique to Infini-Mix. While most mixer companies focus on HIGH SHEAR, Infini-Mix offers the widest range of mixing intensities.